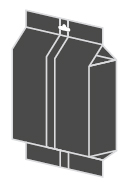

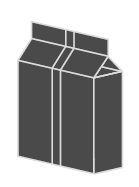

The innovative technical solution, the use of quality materials and reliable components in combination with the efficiency and simplicity of operating the packaging machine represent the best solution for the needs and technical requirements of any customer. A wide range of types and sizes of bags, high performance, robust construction, and yet elegant appearance will satisfy even the most demanding.

It may be used as stand-alone or as a part of a complete filling, packaging and cartoning line.

Continuous automatic vertical packaging machine is suitable for high performance applications. The machine is equipped with a control system with the possibility of program preselection, foil centering, remote machine management, additional equipment for bag forming and other functions. Packed volume up to 5 litres.