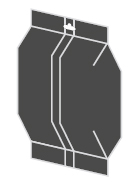

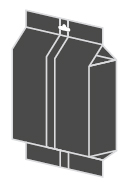

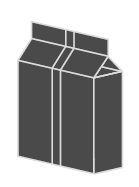

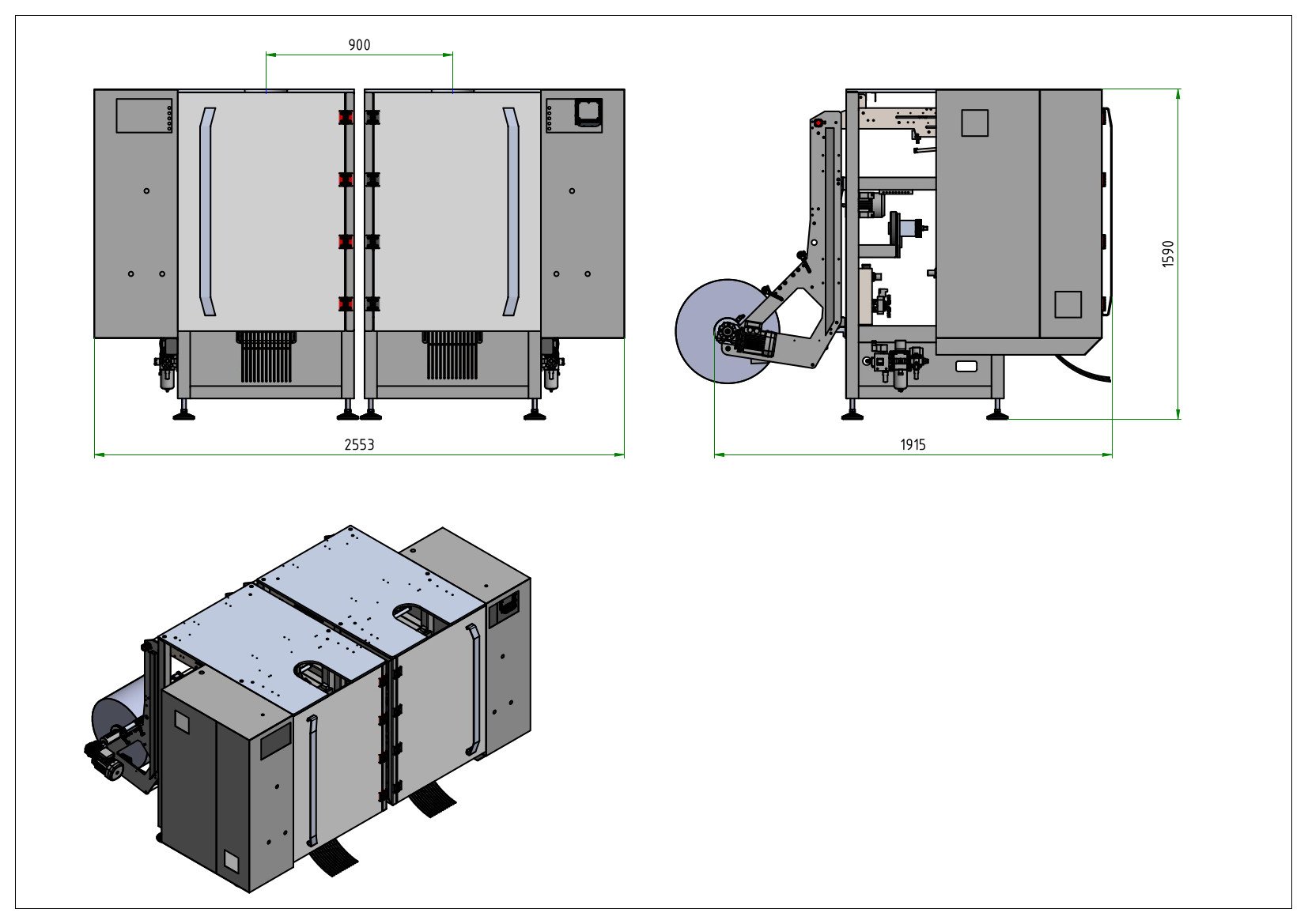

Double performance with a smart solution by combining two high-performance single-lane vertical packaging machines. The use of quality materials and reliable components will ensure flawless production. Efficient and simple operating machines are the ideal solution for confined spaces with high performance requirements. A wide range of bag types and sizes, robust construction and compact solutions attract 100%.

Vertical packaging machines are suitable for all types of production requirements and are designed for the creation of bags made from a roll of heat-sealable packaging material with simultaneous automatic filling of goods and closing the bag.