Search term must have more than 2 characters.

BOX 60H mini

The fully automated horizontal cartoning machine shapes, folds, seals on one side, doses, horizontally fills, closes and seals on the other side, prints and moves the carton for further manipulation. It can work without problems with different shapes and sizes of cardboard boxes pre-glued on one side, as well as with a wide range of filled piece products, either single or in a group. The actuators ensure fast and smooth operation of this cartoning device, which has only minimal maintenance requirements. The machine is controlled by a freely programmable control system with a touch screen.

Machine output:

3600 packages/hr.

Box size:

up to 80x180x75 mm

Piece commodities:

groups of smaller products (broth cubes) or single products

-

SPECIFICATIONS

- Control system: B&R programmable, touch screen

- Machine cycle: discontinuous

- Safety features: main switch, Emergency Stop, end switches on the door

- Surface: varnished steel, stainless steel

- Machine drives: decentralized, electromechanical, combined with pneumatic

- Types of packages: carton boxes (pre-glued on one side)

- Packed products: pieces, product groups

- Includes: box erector, glueing/flap closing

- Others: smooth change of bag length, machine output, advance of product dose

free compilation of configuration and display of error messages on the control panel

storage of up to 100 programs / parameters

remote diagnostics and basic service and modification of the program via modem

-

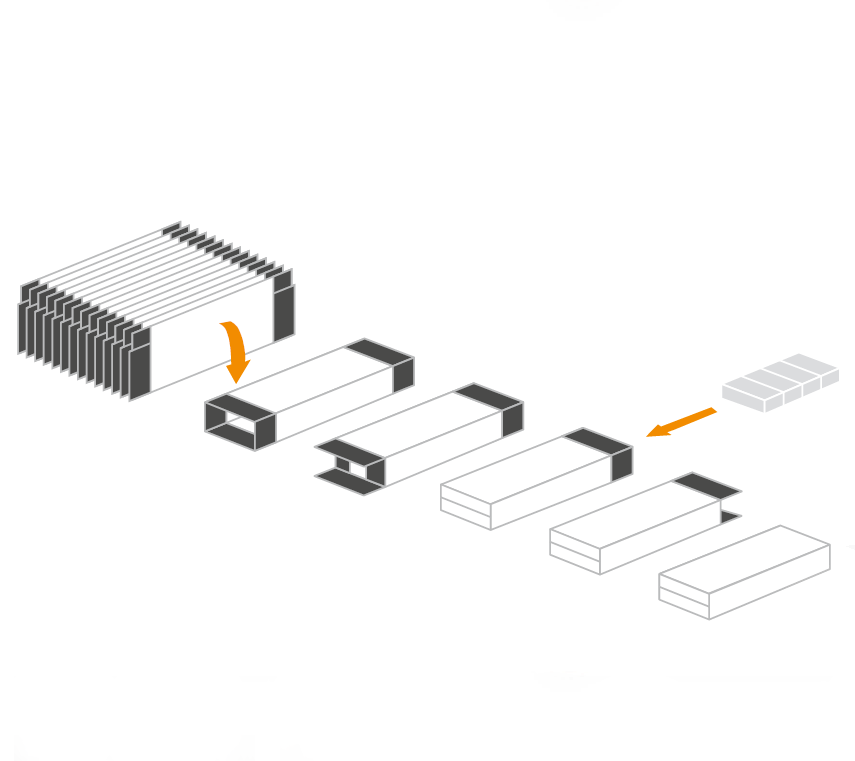

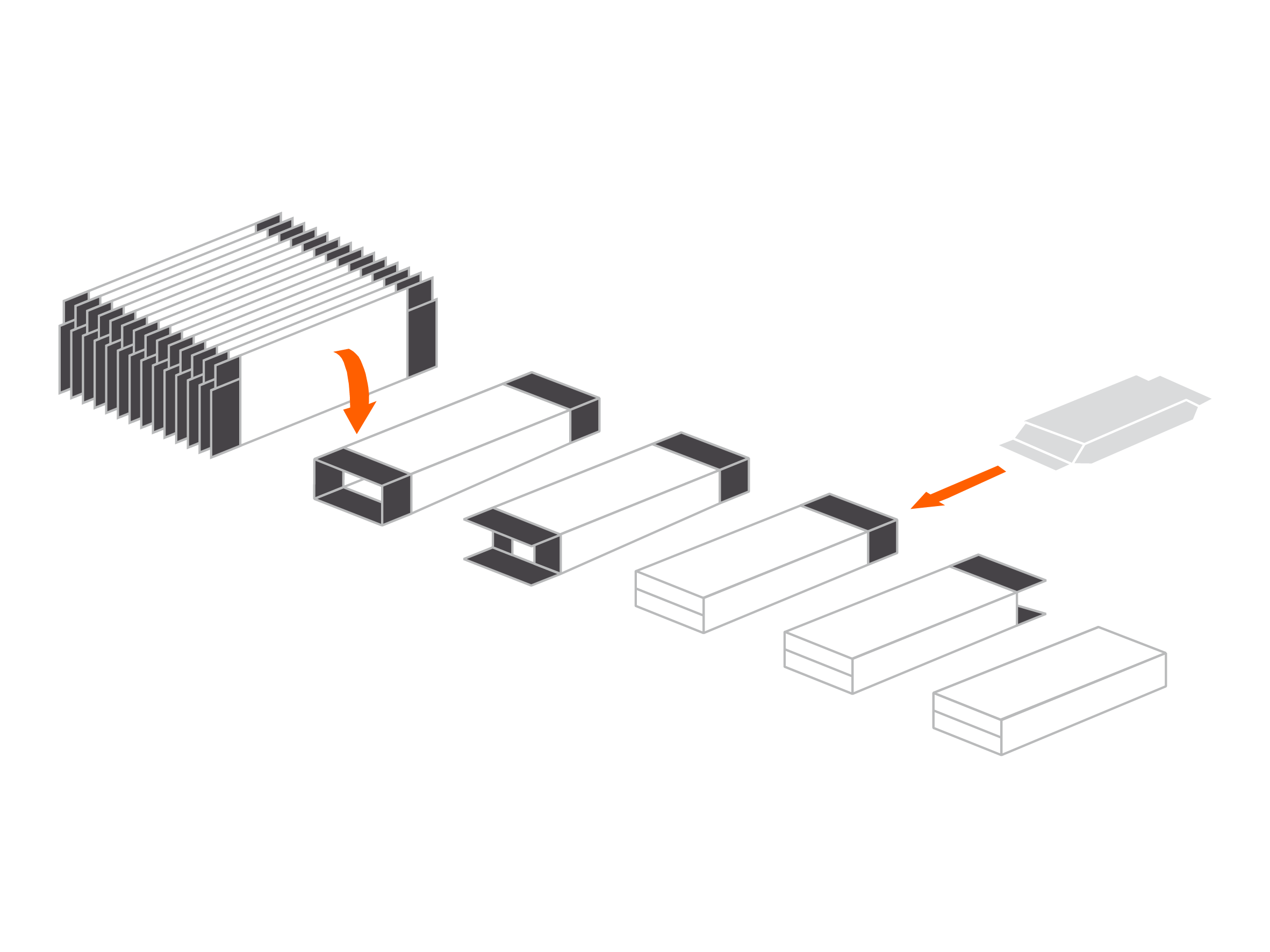

CARTONING SYSTEM

-

PARAMETERS

- Package dimensions: width 20-80 mm | length 70-180 mm | height 13-75 mm

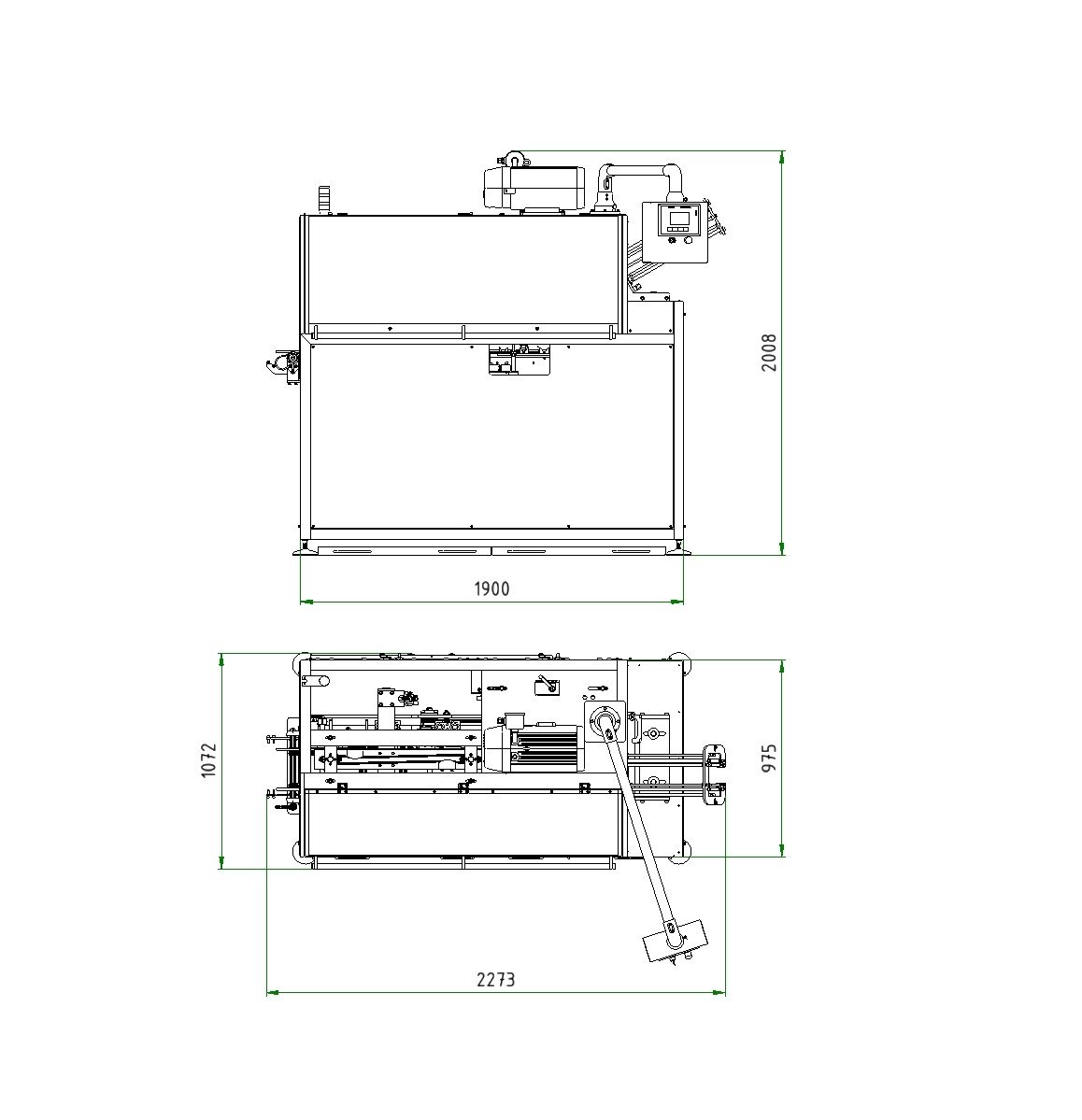

- Dimensions: frame height 1935 mm | depth 3810 mm | width 2100 mm

- Weight: 950 kg

- Mechanical output: up to 3600 packages/hr.

- Output with dosing: depending on product type, carton type and size

-

ACCESSORIES

- conveyors: conveying systems

- marking device (date, bar code, expiry date, etc.)

- labelling equipment

- automatic packages dispensers

- adjustable hoppers

- sorting and counting systems

-

DRAWING

Are you interested in our horizontal cartoning machine BOX 60H mini?

I will recommend the most suitable packaging, cartoning or bagging equipment from our production program and propose a solution according to a specific project.