Search term must have more than 2 characters.

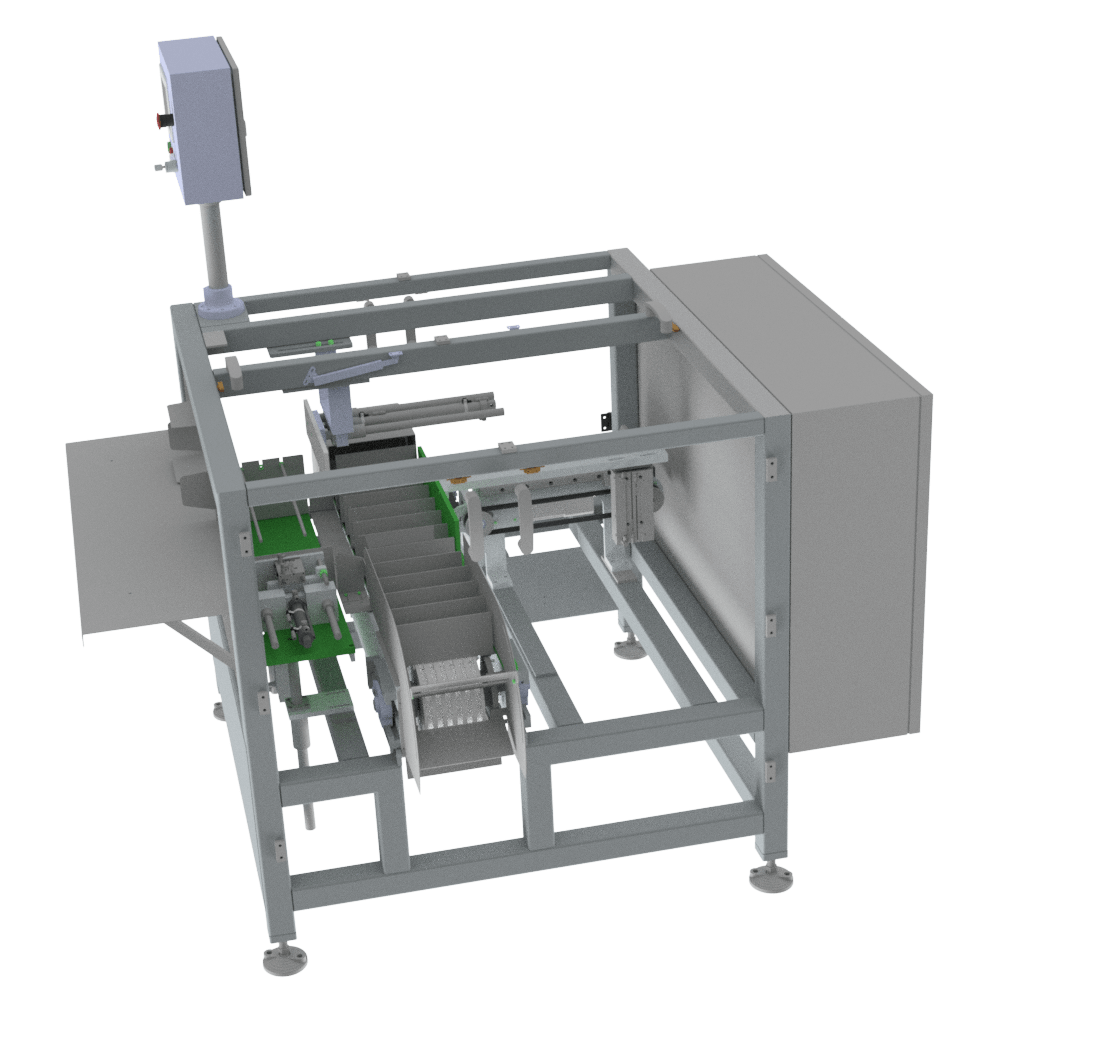

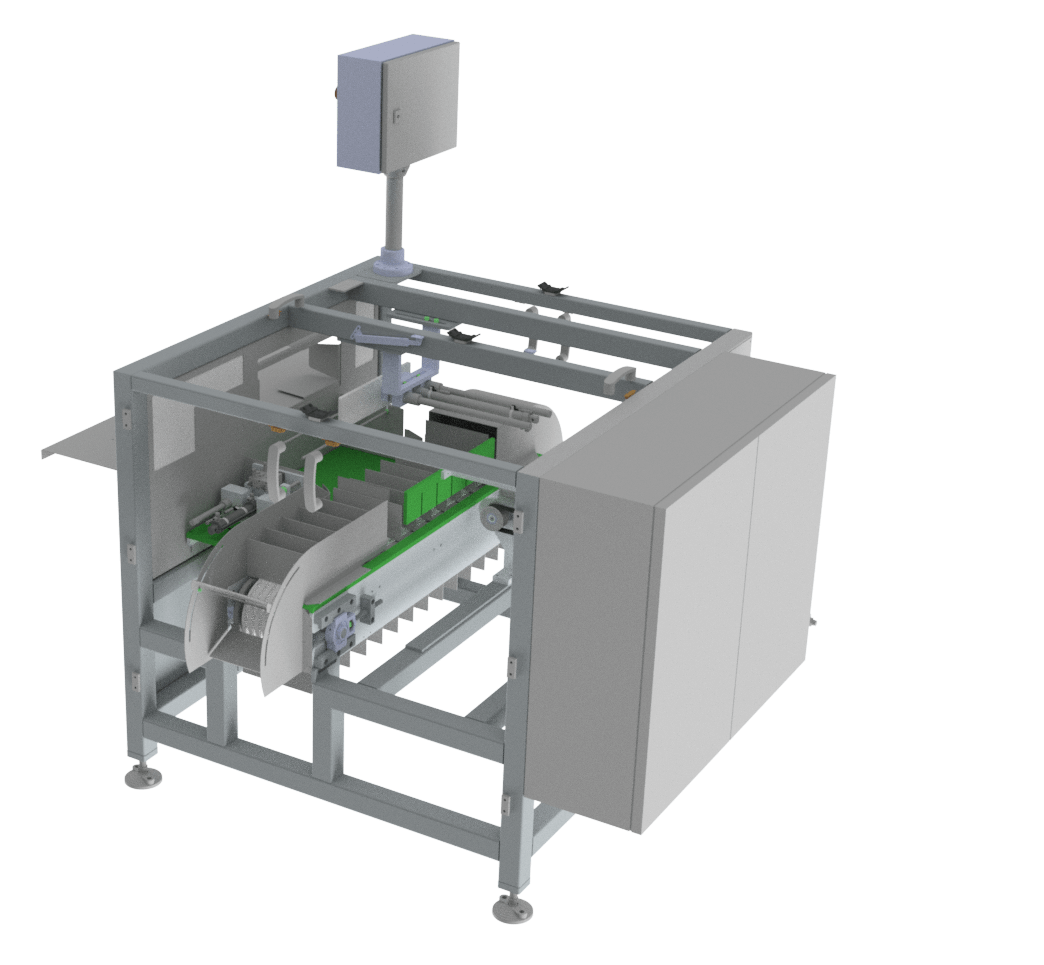

BOX GROUP POLO

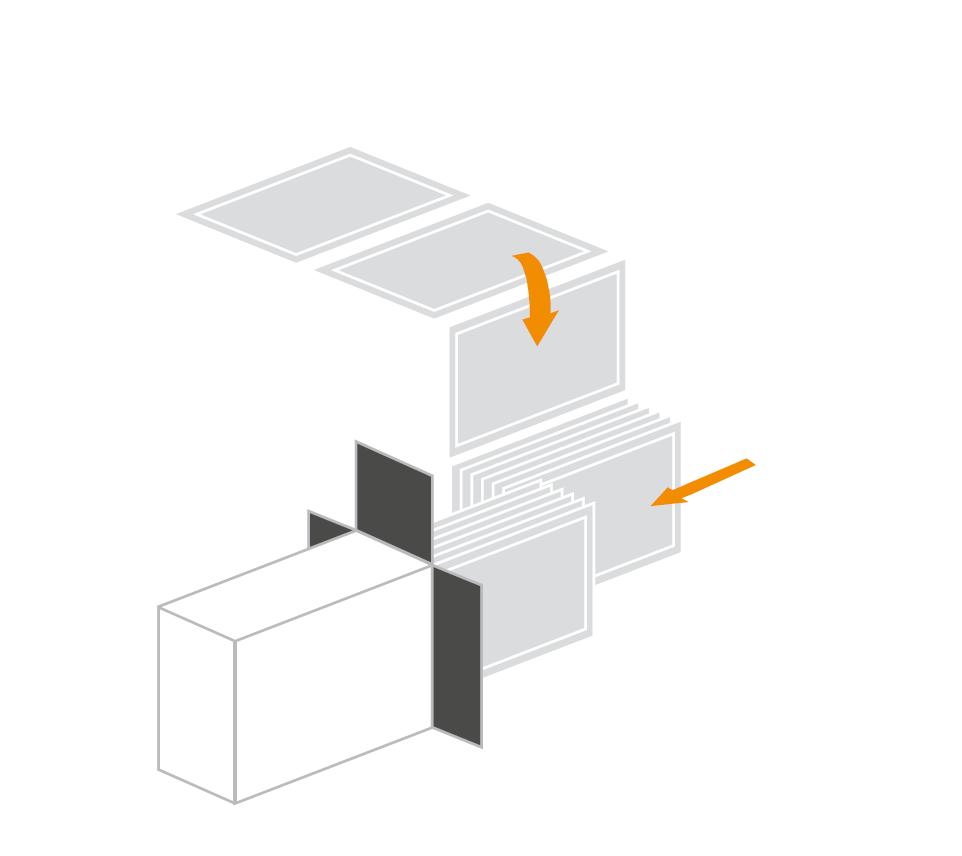

Semi-automatic horizontal cartoning machine suitable for packing different types of bags into manually erected cartons. The bags are brought to the machine from the production machine in one or two rows, are automatically grouped into the required group, moved to the exit of the machine, and then the boxes are automatically inserted horizontally. The operator manually slides a hand-folded cardboard box onto the exit of the machine. The operator then manually removes the full box and immediately slides on another empty box. The filled box is manually closed, glued and handed over for further manipulation. The machine is most often used to speed up the packaging process in conjunction with a horizontal machine. Servo drives ensure fast and smooth operation of the machine with minimal maintenance requirements, pneumatic elements ensure trouble-free movements and transfers of groups of bags and full boxes. The machine is controlled by a freely programmable control system with a touch screen. It is suitable for smaller operations with lower requirements for automation.

Machine output:

up to 200 packs/min.

Cardboard box dimensions:

individual

Piece commodities:

bags, boxes and piece products

-

CHARACTERISTIC

Control system: B&R programmable, touch screen

Machine cycle: step

Machine drives: decentralized, electromechanical, combined with pneumatic

Safety features: main switch, Emergency Stop, end switches on the door

Sensors: monitoring of product and cartons in individual stations of the machine

Surface: varnished steel

Packages type: manually folded carton box

Packed products: pieces (bags, boxes) -

BAG TYPES

-

PARAMETERS

Dimensions: machine frame height 1780 mm / depth 1770 mm / width 1530 mm

Weight: 500 kg

Product dimensions: bags min/max

Package dimensions: min/max

Mechanical output: up to 200 packages/min.

Output with dosing: dependeing on product type, carton type and packed amount

Others free compilation of configuration and display of error messageson the control panel

programmable control system

storage of up to 100 programs / parameters

remote diagnostics and basic service and modification of the program via modem -

ACCESSORY

- conveyor systems

- marking device (date, bar code, expiry date, etc.)

- labelling equipment

- sorting and counting systems

- automatic carton storage/dispenser

Are you interested in our machine BOX GROUP POLO?

Are you looking for a packaging solution? We have a wide range of different packaging machinery. Contact me for more information.