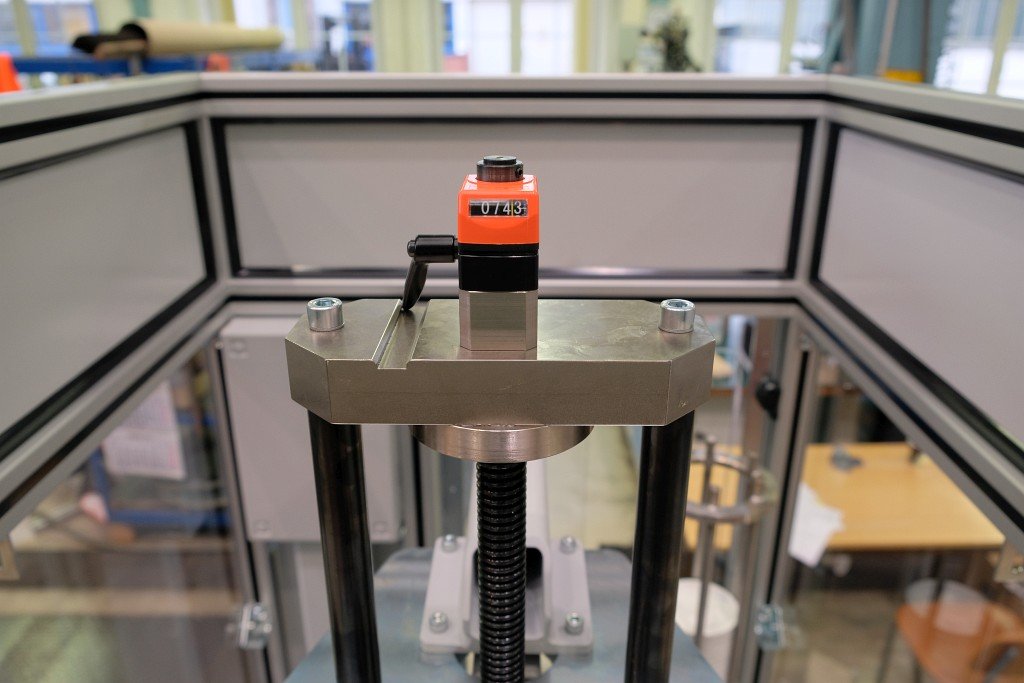

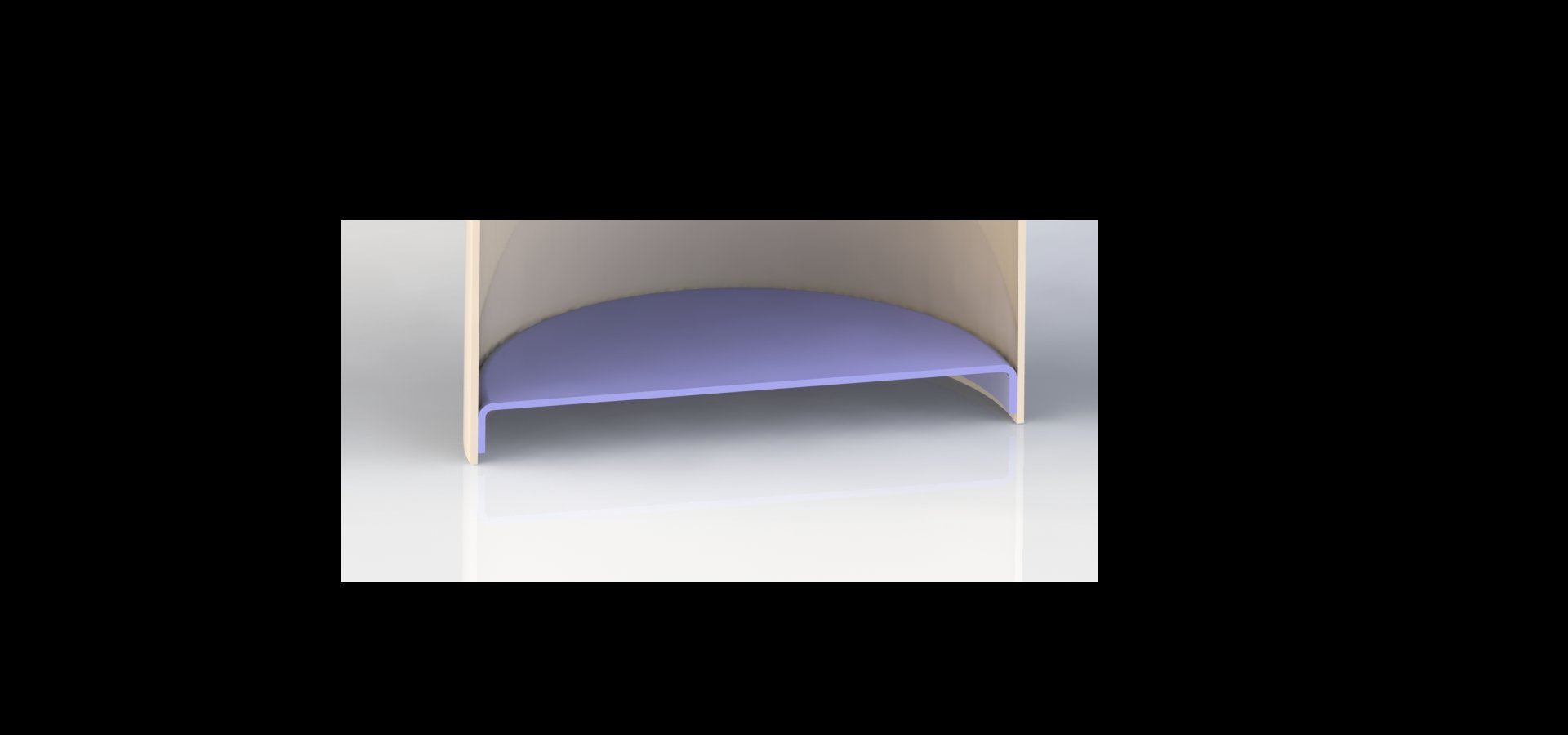

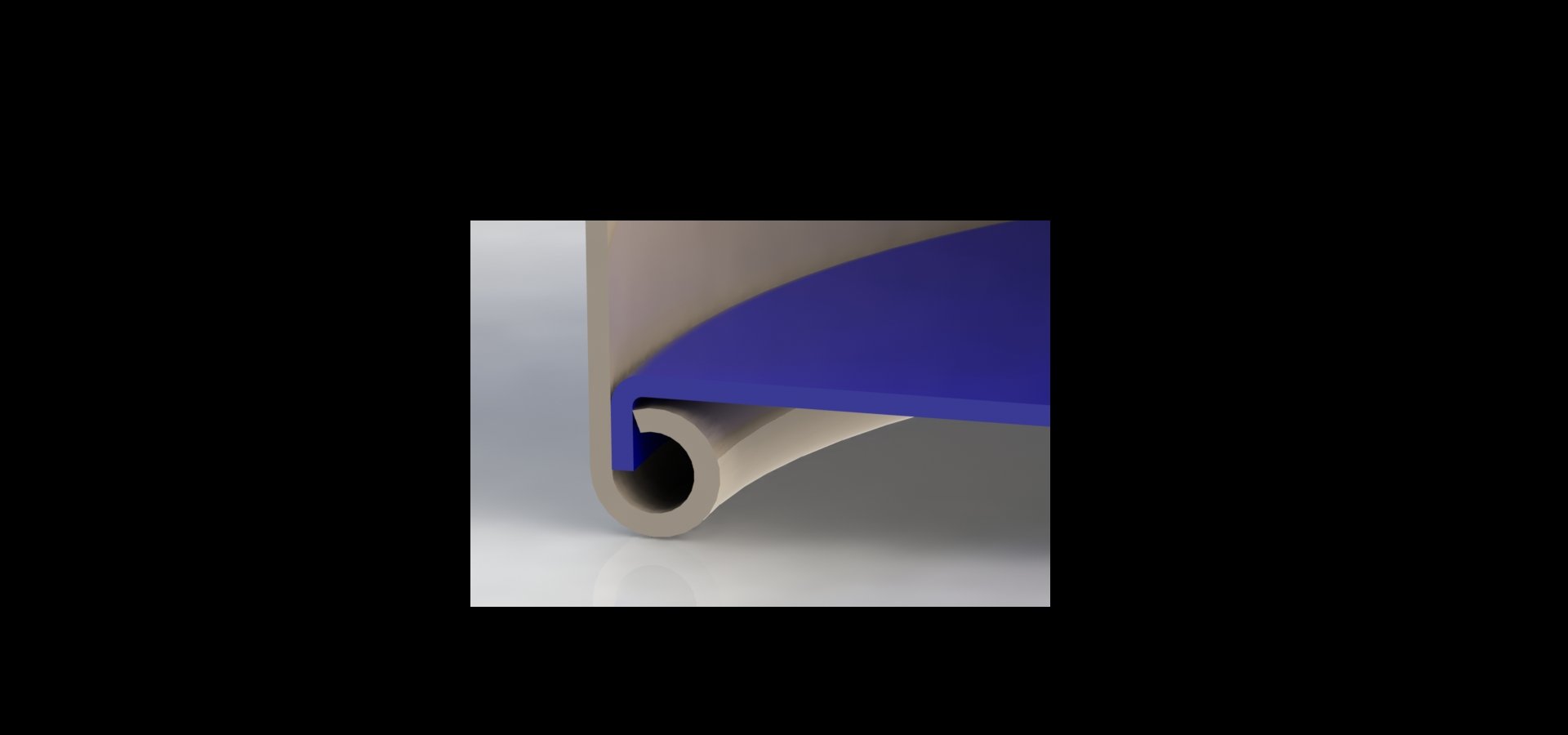

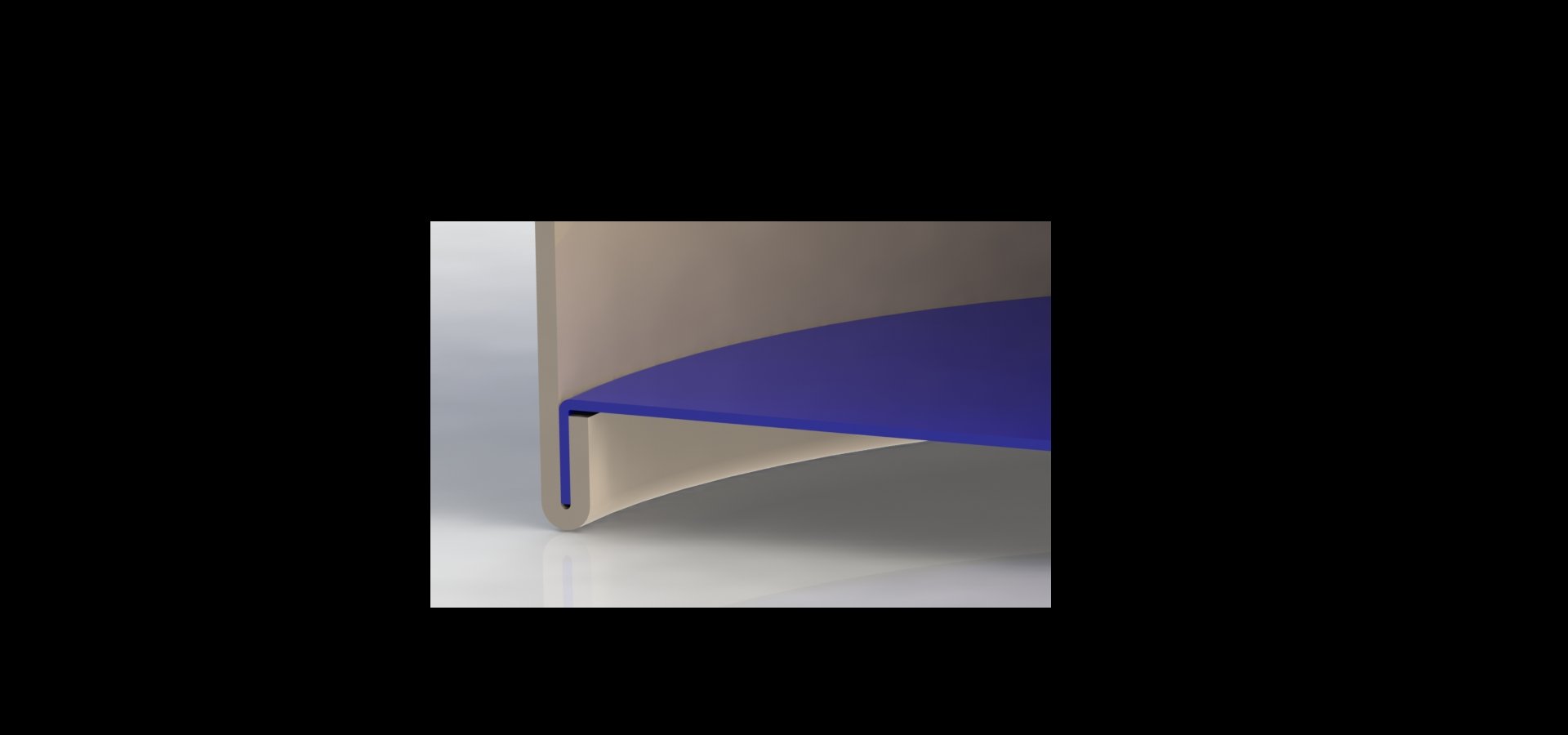

The station is capable of sealing multiple container formats (height, diameter, and volume) and is always adapted to customer requirements. Format changeover is very simple and fast, with automatic height adjustment, eliminating the need for part replacement.

Optional control devices can be added, including prevention of sealing when a container or bottom is missing, overheating protection during sealing, automatic pneumatic ejection of defective containers, and integration of vision inspection systems.