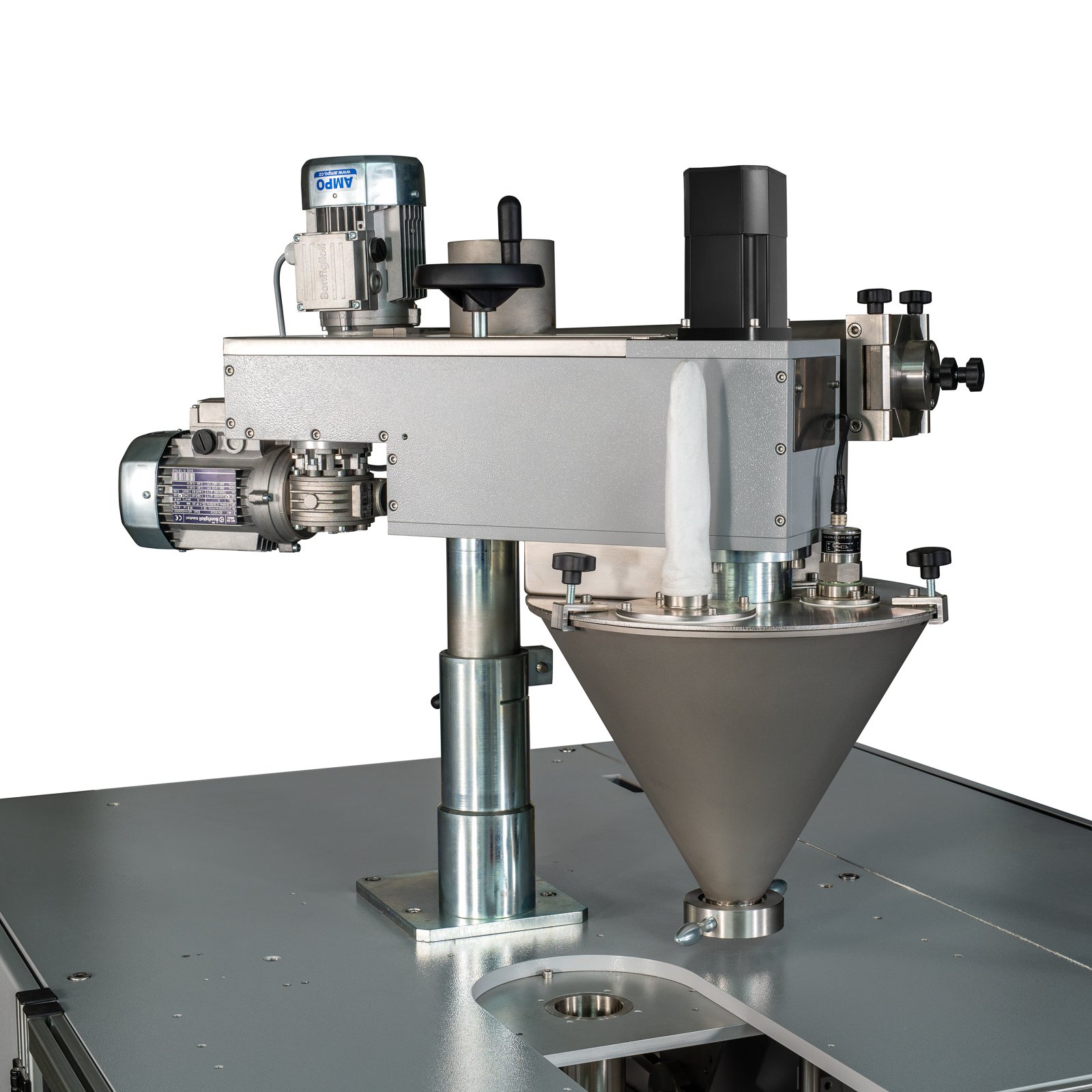

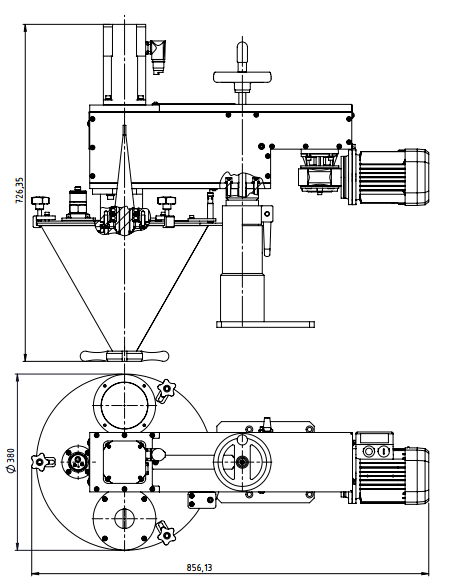

RACKET S micro type auger dosing devices are designed for volume dosing of powder products. Depending on the type, the dosing machines may be fitted with an asynchronous motor or servomotor.

Machine control system using a touch-screen display with 100 preselected parameters. Screw dosing machines are offered as mini, standard and maxi variants.