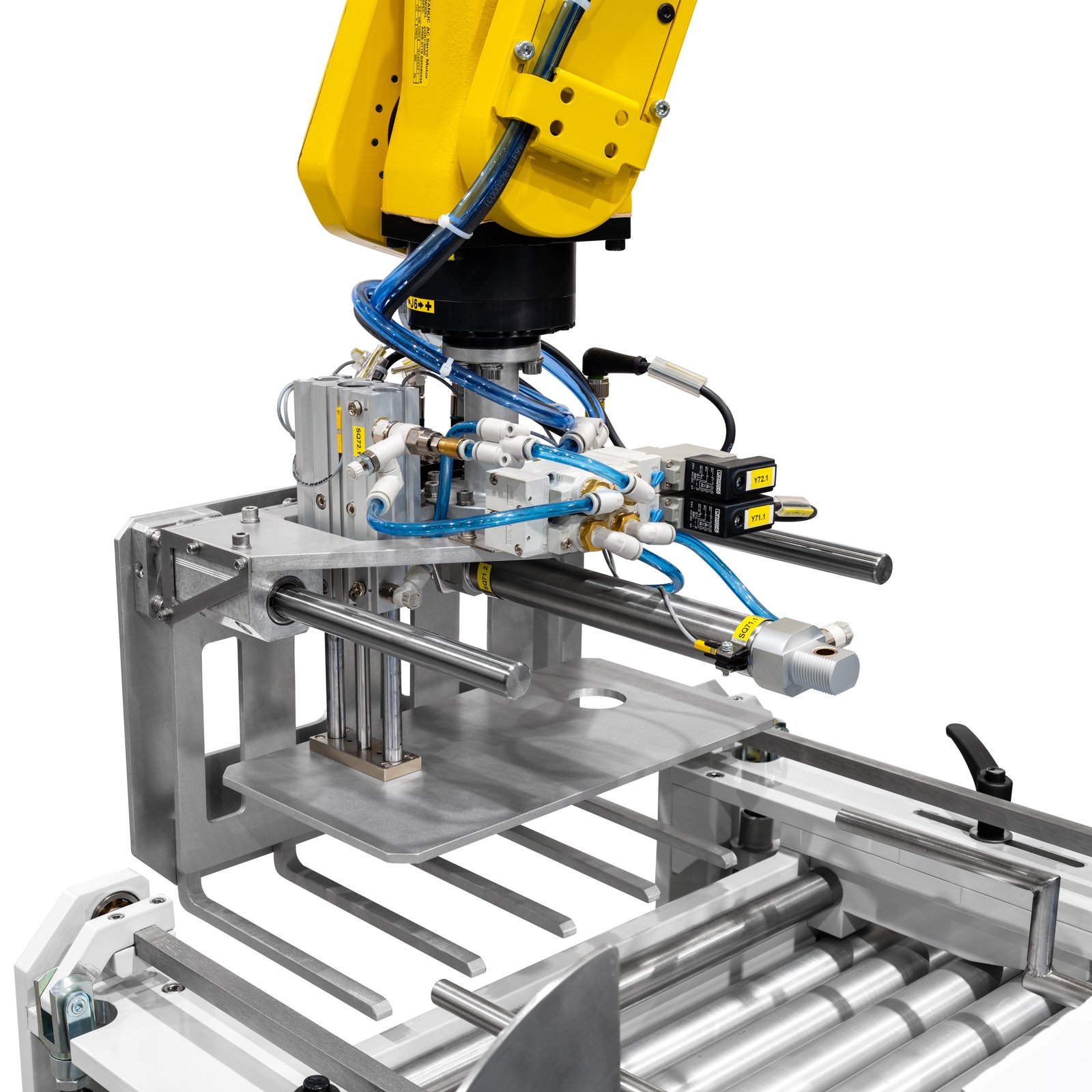

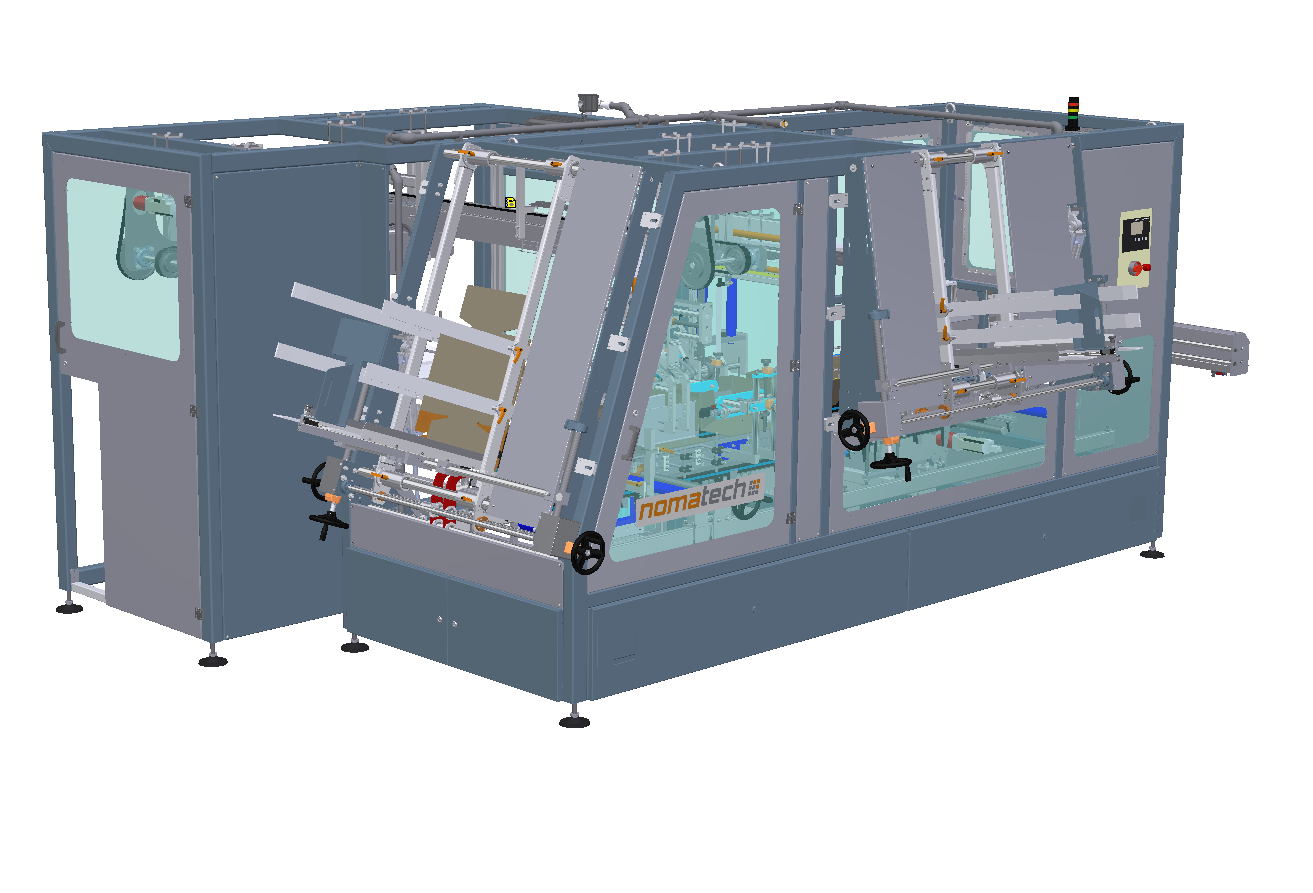

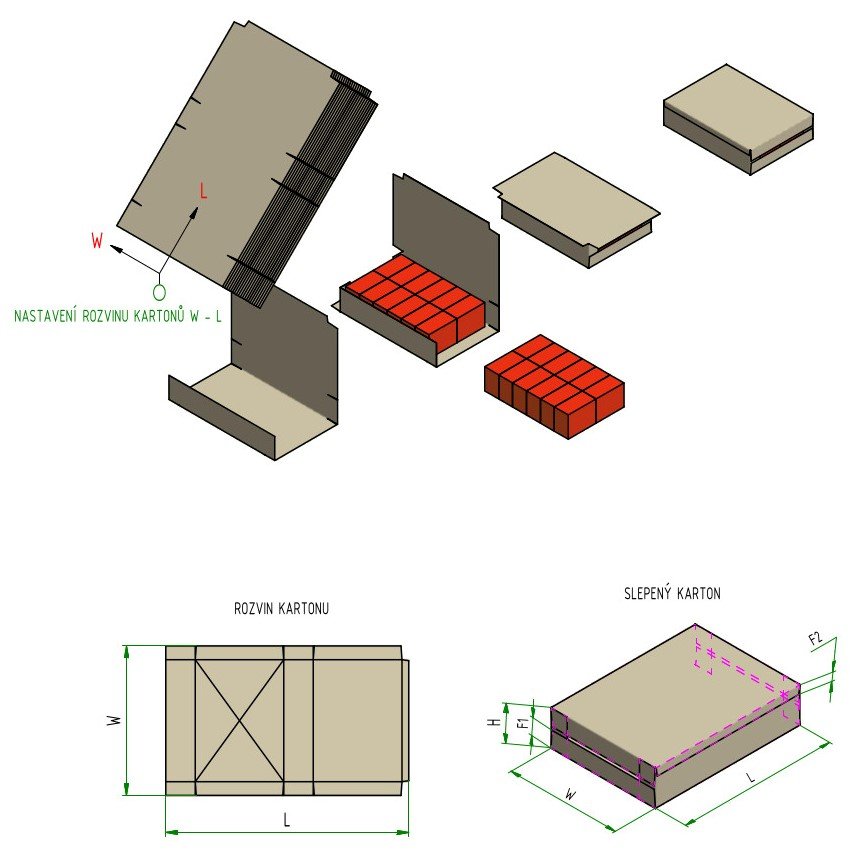

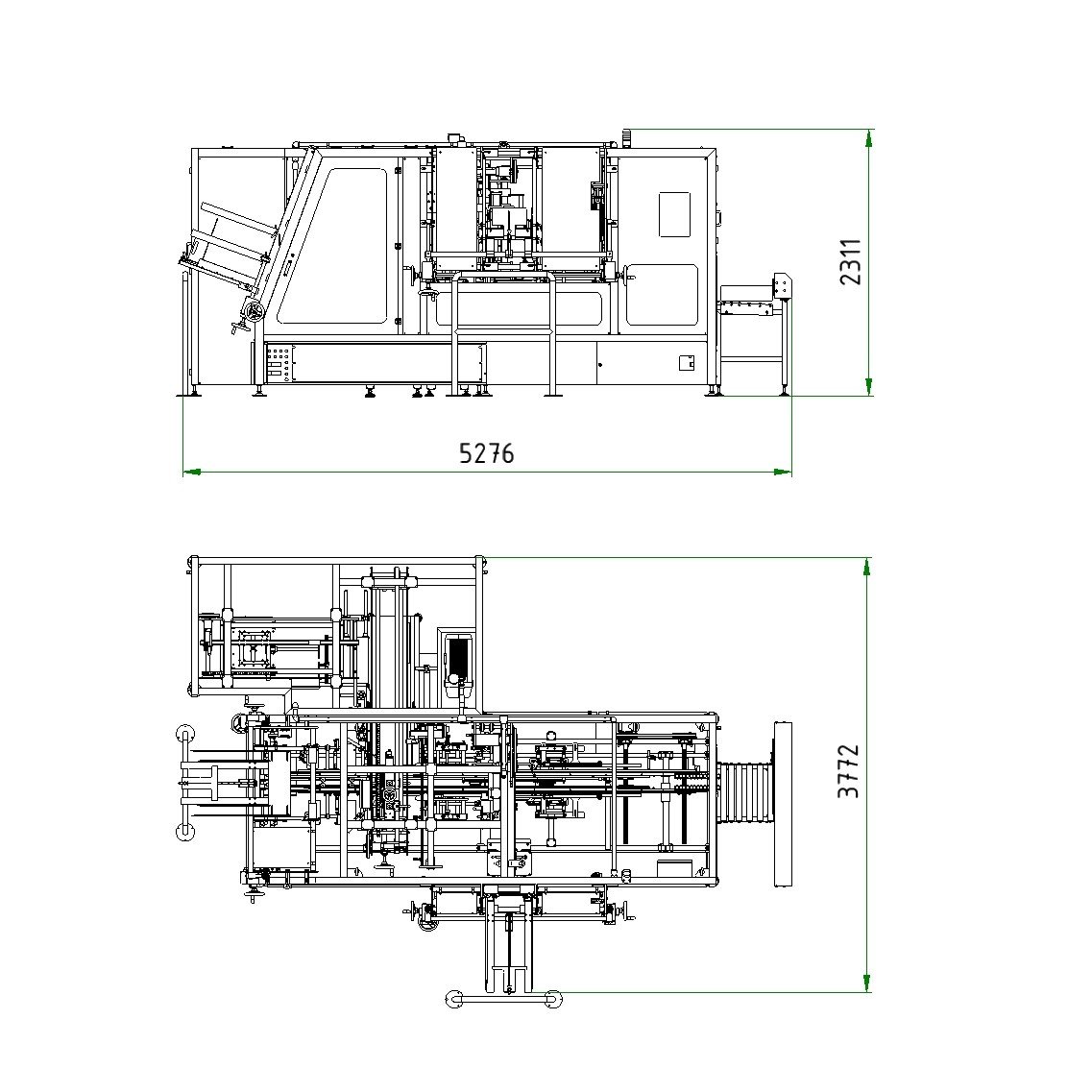

Cartoning line CASE is designed for cartoning a group of pre-filled glass jars, bags or boxes into cardboard boxes. The fully automatic line groups the required number of products according to the selected range, shapes and folds a cardboard package from blanks, into which the prepared group of products is inserted vertically using an inserter. Filled bags or boxes are fed from the packaging machine by a dosing conveyor, which ensures accurate dosing into the compartments of the grouping system. The box is then closed and sealed and moved to the exit conveyor for further handling. The device can work both with different sizes of cardboard boxes and trays, as well as with a wide range of filled piece products within the specified size range. All functions of the line are controlled via the touch screen. The required size of the carton is set on the adjustable formatting matrix. Drives are handled by servomotors in combination with asynchronous drives and pneumatic elements for fast and smooth operation. The carton magazine can be adjusted in 2 axes, the adjustment is carried out by hand wheels (length, width, depth of the carton). The cartons are sealed with hot melt glue with a Nordson gluing unit.

Search term must have more than 2 characters.