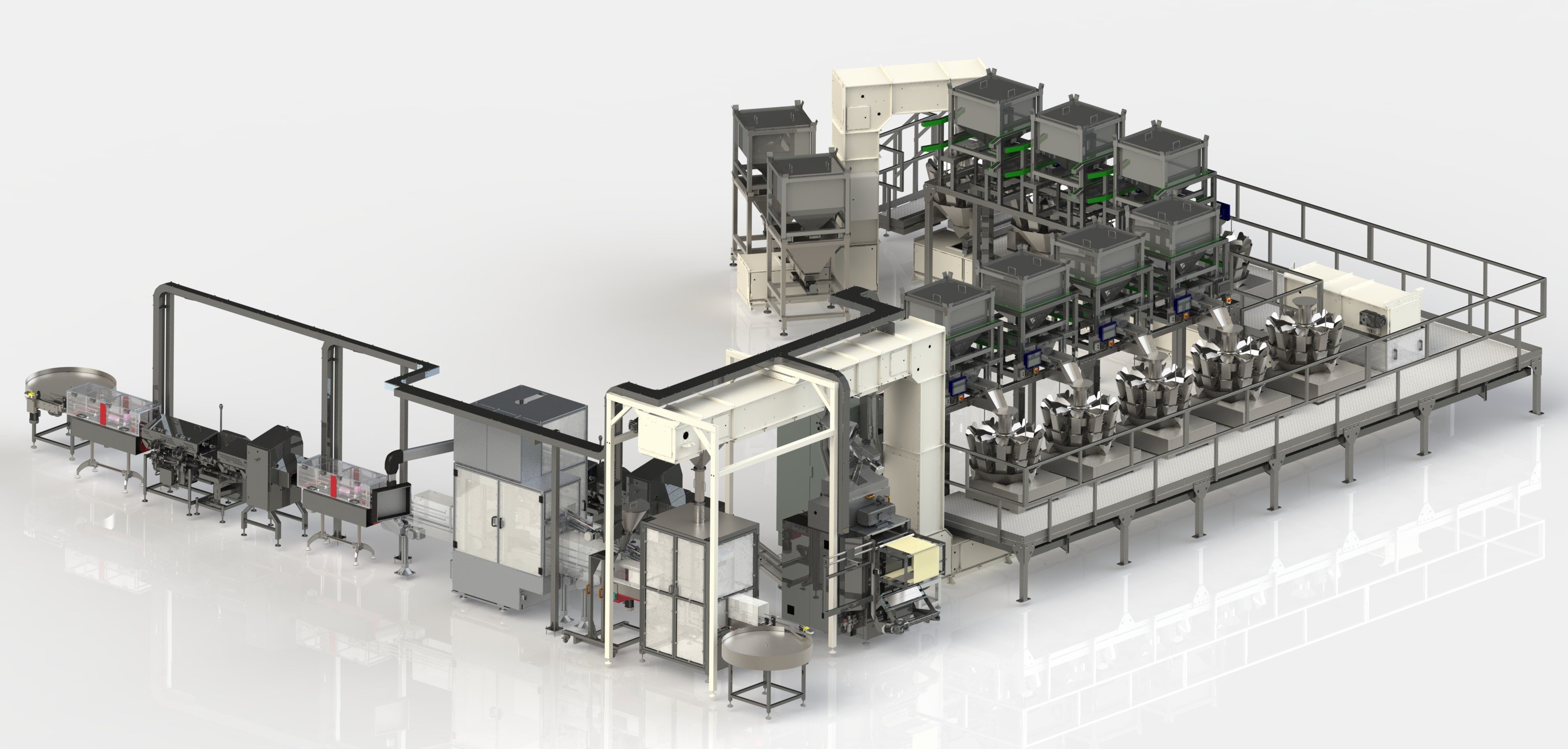

A fully automated filling station is designed for the purpose of filling tubes or cups with loose, powder or small piece product in a pre-set dose, it is always equipped with a suitable dosing device according to the product being filled (multihead weighers, auger or volume dosing unit). The filling station is usually composed of two filling points, to which empty containers are transported along the conveyor belt, filled with an appropriate amount of product and moved for further handling (application of lids, cartoning).

The filler is capable of filling multiple packaging formats (they differ in height, diameter and volume), we always adapt the machine to the customer's requirements. Conversion to another format is very easy and fast.

The filling station is ideal to include in a complete line for moving, filling and capping tubes, cups and cans.