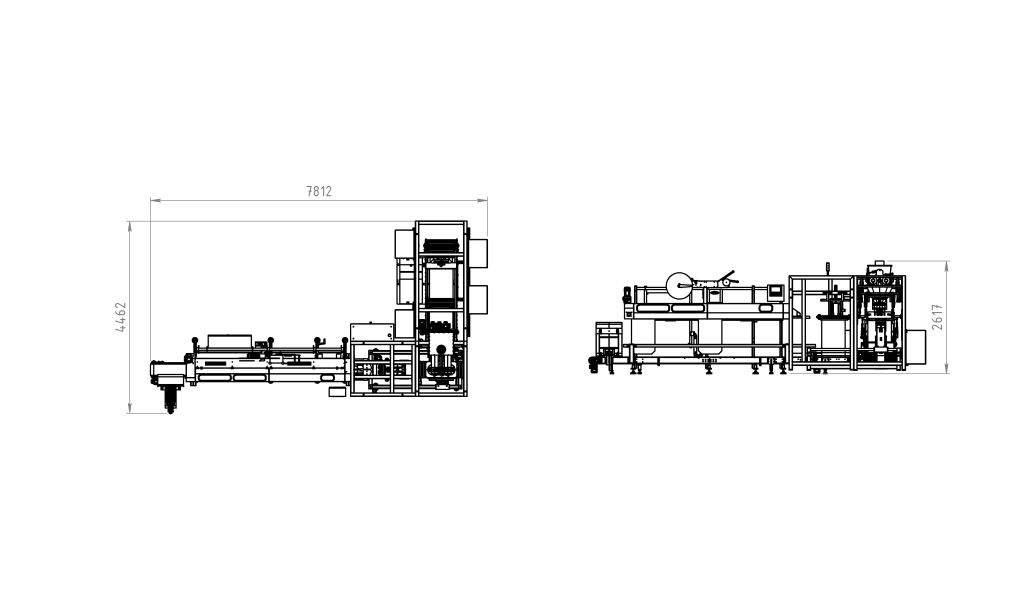

Fully automated bagging equipment is an ideal solution for various requirements for filling goods into premade paper or plastic high-volume bags. It ensures trouble-free filling of larger gastro packages g up to a volume of 25 l, such as pasta, granules, flour, feed mixtures, powdered milk, pellets or sugar. Depending on the type of filled product is the device equipped with a suitable dosing device. It is flexible in many ways, from the bag volume, the variety of packaged goods to several types of bag closures. The bags are removed from the storage by means of suction cups and bag holders open the bags for product filling. The full bag is further moved to a closing station (glueing, sewing, stretch tape) and/or further handling, e.g. palletising.

Search term must have more than 2 characters.