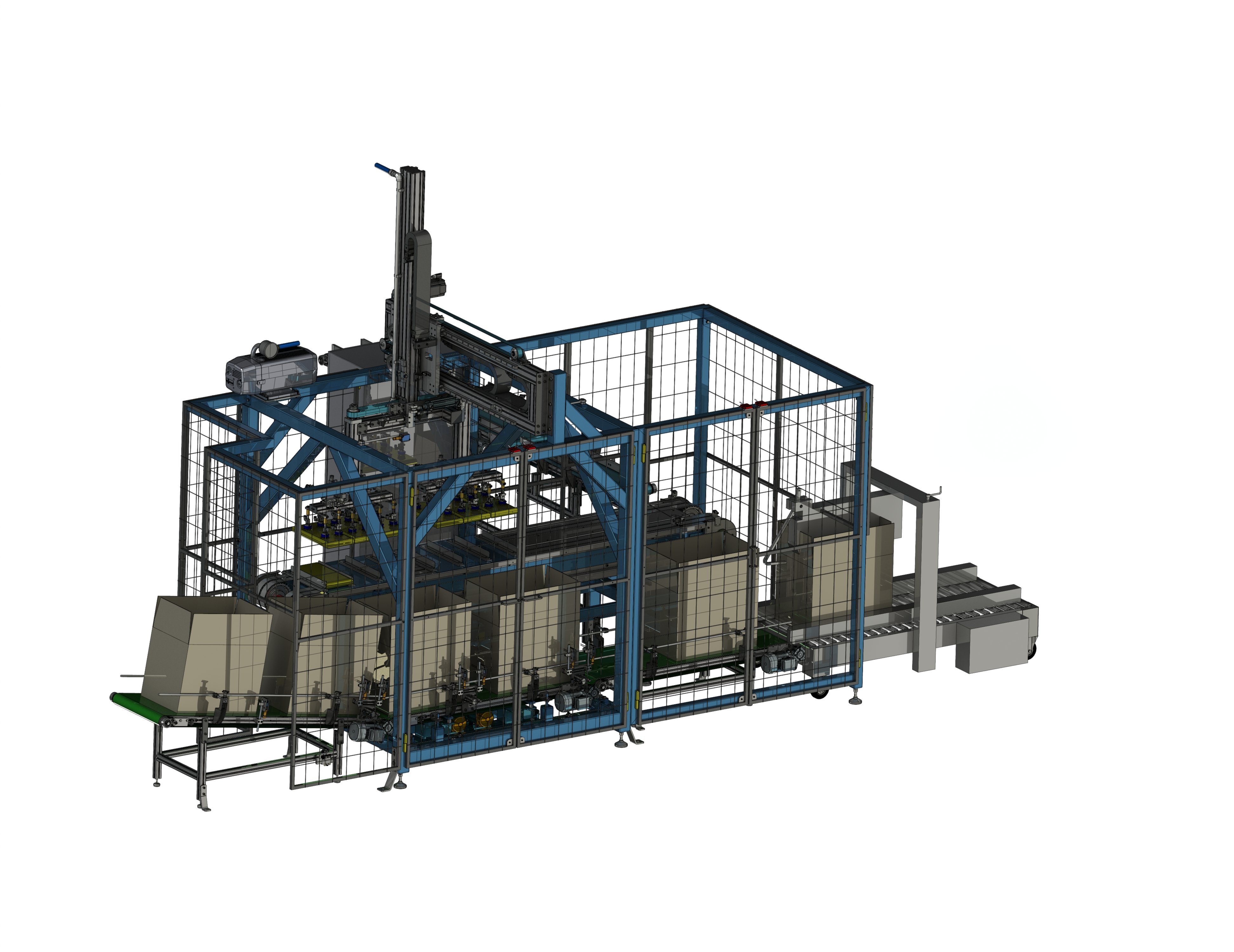

Fully automated manipulator is designed for efficient automation of cartoning. Its main function is to place bags or boxes into cartons using a suction-cup-equipped arm. The automated arm picks up groups of bags or boxes from the infeed conveyor and arranges them in a predefined grouping inside a folded carton in multiple layers. Once filled, the carton is conveyed to the closing and sealing unit.

The manipulator is always configured individually according to the specific application. The number of suction-cup-equipped handling arms may vary depending on customer requirements. The manipulator can work with different packaging formats and types (height, width, length, number of items per group, number of filled packages, etc.) and allows for quick and easy format changeovers.

This manipulator is most commonly integrated into a complete packaging line tailored to the customer’s needs. Bags can be produced and filled on the TOBOGAN vertical packaging machine, while boxes are filled using the BOX cartoning machine. Cartons are formed by a carton erecting machine and subsequently sealed by a sealing unit. Sealed cartons can then be palletized using the ROBO PAL robotic system, maximizing the efficiency of the entire process.

Search term must have more than 2 characters.