Search term must have more than 2 characters.

MH 170 FE SIMPLEX | DUPLEX

MH series horizontal packaging machines are designed for the production of flat bags (3 or 4 seals) from a heat-sealable roll of packaging material. The machine can be used for packing small pieces, granular, light-flowing, heavy-flowing, pasty and liquid products. The machine allows packing several components into one bag.

Machine output:

40-50 packs/min.

Dose size:

min. 80x130 mm

max. 170x270 mm

Bulk commodities:

sugar, salt, coffee, sugar and other products

sugar, salt, coffee, sugar and other products

Powder commodities:

coffee, ground spices, washing powder, cocoa and more

coffee, ground spices, washing powder, cocoa and more

Liquid commodities:

ketchup, mustard, oil and other liquids

ketchup, mustard, oil and other liquids

Piece commodities:

pasta, candies, frozen vegetables and others

Filled and closed bag or double-bag with three or four sides sealed leave the machine via a slide or an outfeed conveyor for further handling.

The machine has an electromechanical drive and a step operating cycle. Machine control is performed by the control system allowing easy setting of machine parameters.

-

CHARACTERISTIC

- Sealing type: thermal

- Packed products: loose, dusty, bite-sized, liquid, pasty

- Control: control panel

- Bag types: flat bags with 3 or 4 sealed sides

- Machine drives: electromechanical

- Machine cycle: step

- Machine surface: varnished, stainless steel design

-

BAG TYPES

Flat 4SS

Flat 4SS

Flat 3SS

Flat 3SS

Flat duplex 3SS

Flat duplex 3SS

Flat duplex 4SS

Flat duplex 4SS

Doypack

Doypack

Doypack + zipper

Doypack + zipper

Standing bag

Standing bag

Standing bag with zipper

Standing bag with zipper

-

PARAMETERS

- Bag dimensions (width x heigth): min. 80x130 mm | max. 170x270 mm

- Device dimensions (width x height x length): 1295x1895x5700 mm

- Filled amount: 1000 cc

-

ACCESSORY

- automatic dosing units according to product type - auger, volumetric, pumps

- marking device

- systems dust removal

- easy opening

- Euro hole punch system

- zipper, closure applicators

- different types of cutting blades

- conveyor systems, including pick&place system to make bag groups

-

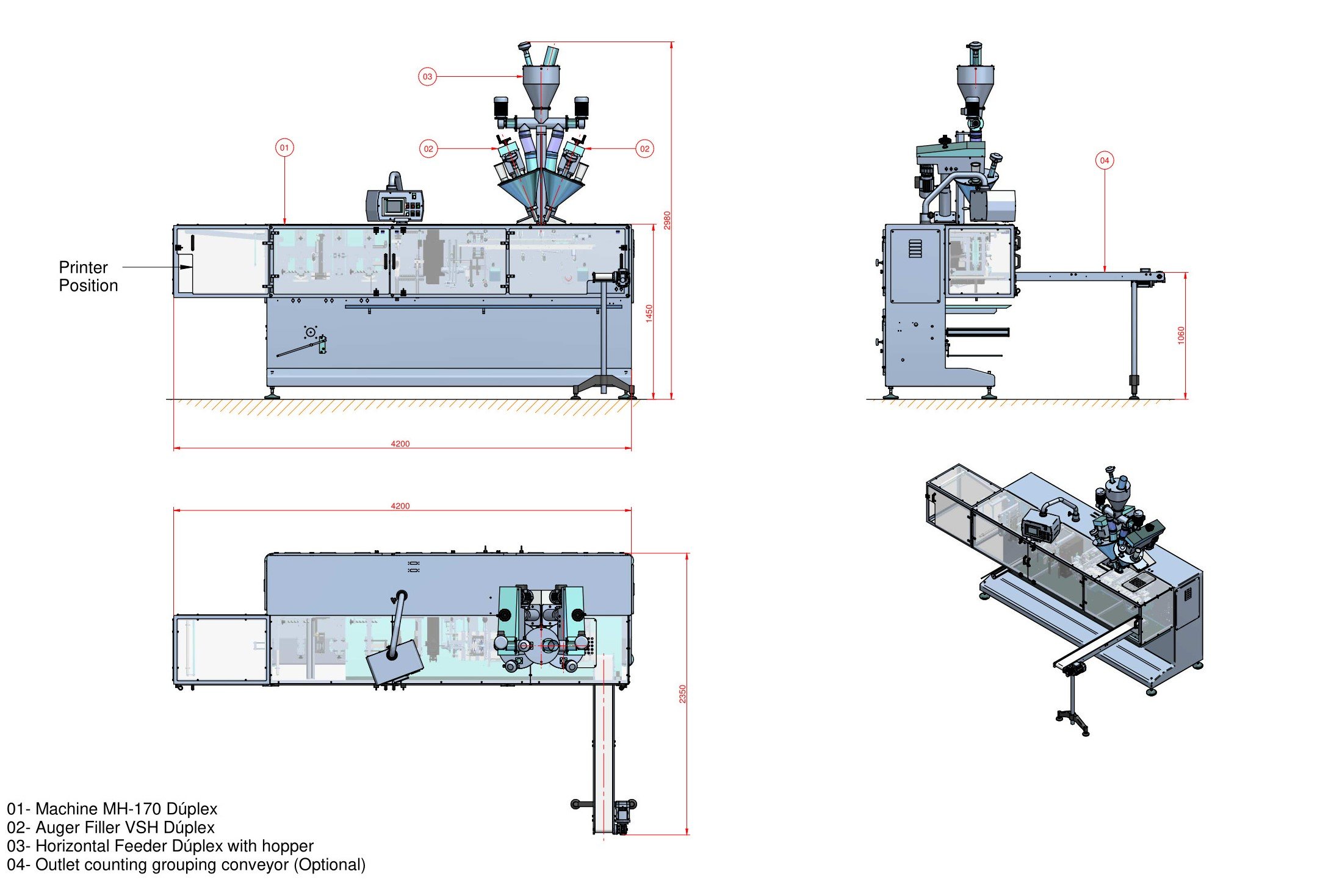

DRAWING

Are you interested in our machine MH 170 FE SIMPLEX | DUPLEX?

I will recommend the most suitable packaging, cartoning or bagging equipment from our production program and propose a solution according to a specific project.