Search term must have more than 2 characters.

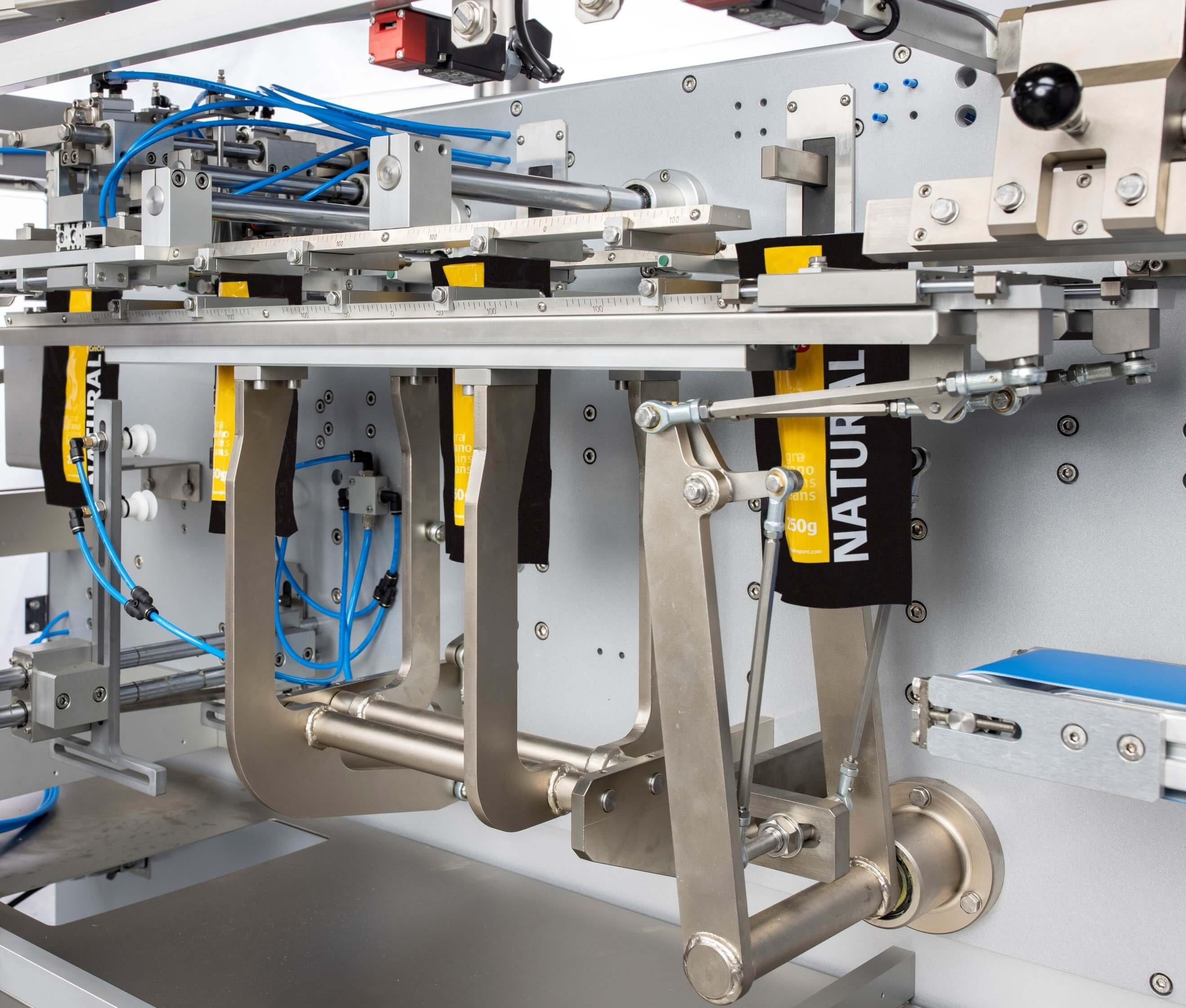

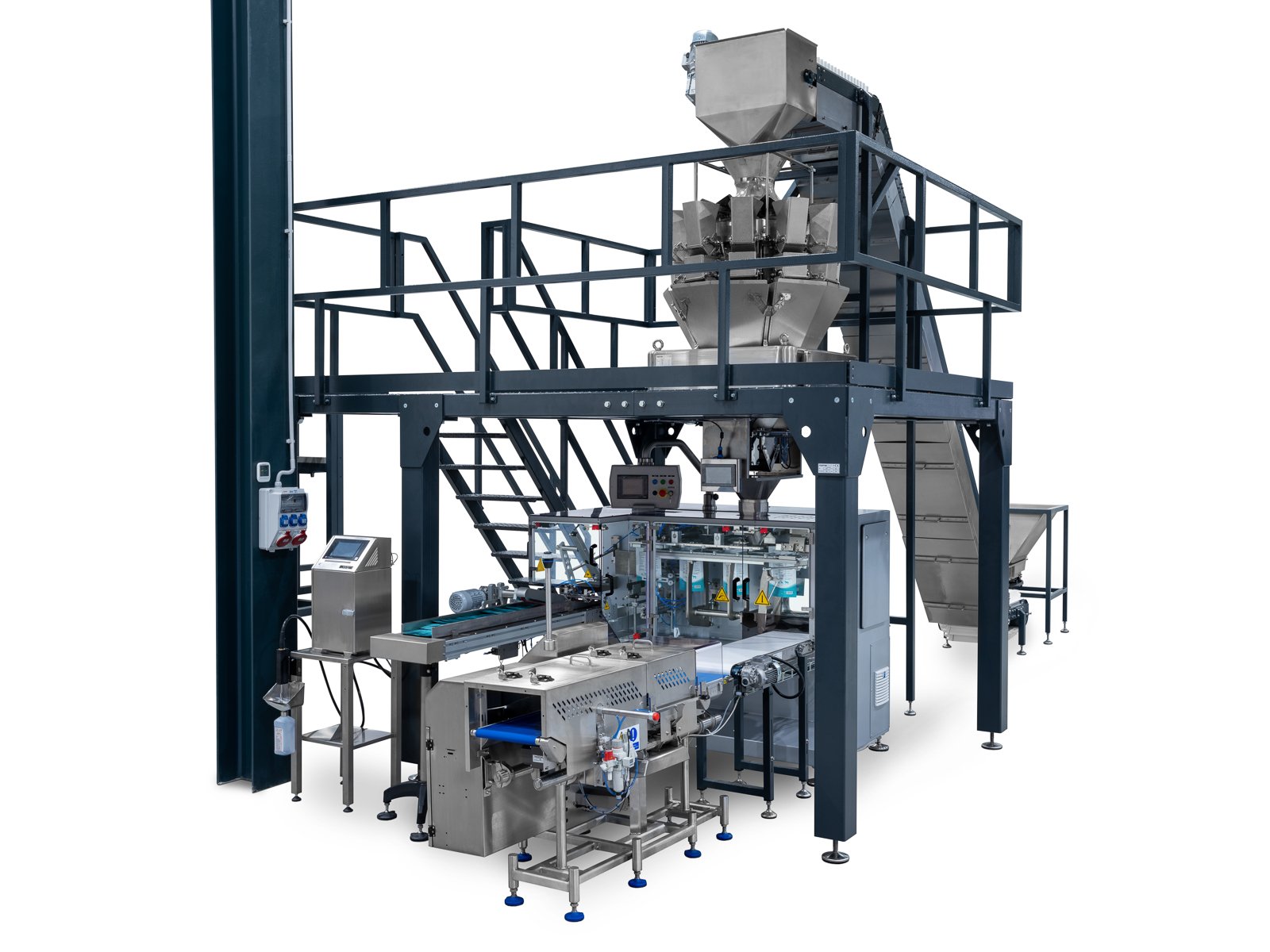

MH 25 SC

MH series Horizontal packaging machines of the linear arrangement are intended for filling premade bags. The machine can be used for packing small pieces, granular, light-flowing, heavy-flowing, pasty and liquid products.

Machine output:

up to 40 packs/min.

Bag dimensions:

min. 100x100 mm

max. 250x300 mm

Bulk commodities:

sugar, salt, coffee and other products

sugar, salt, coffee and other products

Powder commodities:

ground spices, washing powder, cocoa, coffee and more

ground spices, washing powder, cocoa, coffee and more

Liquid commodities:

ketchup, mustard, oil and other liquids

ketchup, mustard, oil and other liquids

Piece commodities:

candies, pasta, frozen vegetables and more

Filled and closed bags or double-bags with three or four sides welded leave the machine via a slide or an exit conveyor for further manipulation.

The machine has an electromechanical drive and step operating cycle. Machine control is performed by the control system allowing easy setting of machine parameters.

-

CHARACTERISTIC

- Sealing type: thermal

- Packed products: loose, dusty, bite-sized, liquid, pasty

- Control: control panel

- Bag types: premade (flat bags, doypacks, with or without zipper)

- Machine drives: electromechanical

- Machine cycle: step

- Machine surface: varnished, stainless steel design

- No. of filling places: 1

-

BAG TYPES

Flat 4SS

Flat 4SS

Flat 3SS

Flat 3SS

Doypack

Doypack

Doypack + zipper

Doypack + zipper

Standing bag

Standing bag

Standing bag with zipper

Standing bag with zipper

-

PARAMETERS

- Bag dimensions (width x height): min. 100x100 mm | max. 250x300 mm

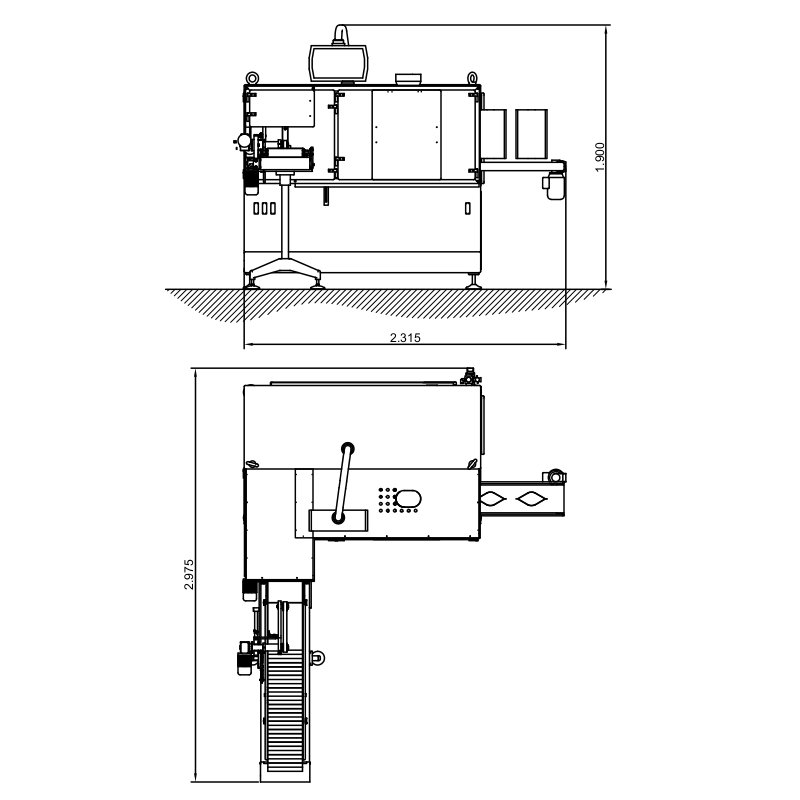

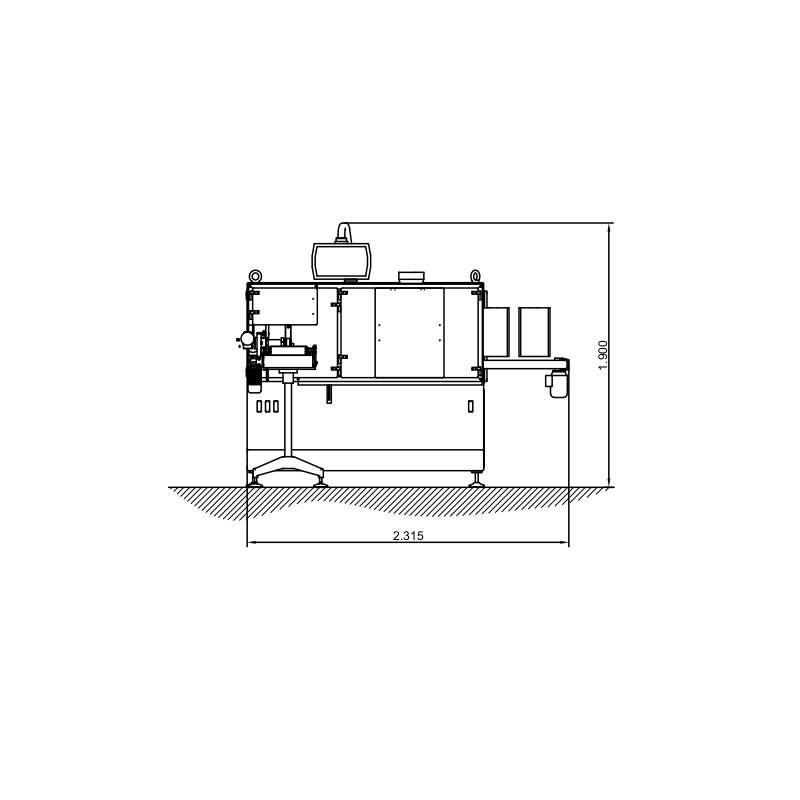

- Machine dimensions (width x height x length): 2975x1900x2975 mm

-

ACCESSORIES

- automatic dosing units according to product type - auger, volumetric, pumps

- marking device

- systems dust removal

- easy opening

- Euro hole punch system

- zipper, closure applicators

- different types of cutting blades

- conveyor systems

-

DRAWING

Are you interested in our machine MH 25 SC?

I will recommend the most suitable packaging, cartoning or bagging equipment from our production program and propose a solution according to a specific project.