Increase Productivity and Safety with Fully Automated ROBO PAL Robotic Palletization

Enhance your production efficiency and safety with the fully automated ROBO PAL robotic palletization system. Our solution enables fast, precise, and reliable stacking of filled cartons or bulk bags onto pallets. It minimizes the risk of product damage while saving time and costs. ROBO PAL is flexible and fully adaptable to different packaging types and formats, with easy reconfiguration options.

What is Palletization and Why Automate It?

Palletization is the process of stacking goods onto a pallet in a predefined arrangement. Automating this process with a palletizer or palletizing line offers:

Faster and more consistent stacking

Reduced workplace injuries and lower risk of product damage

Cost savings and increased productivity

ROBO PAL is a prime example of a modern palletizer, providing full automation from the supply of packaged goods to their placement on a pallet.

How Does ROBO PAL Work?

The robot picks cartons and bags from the supply conveyor.

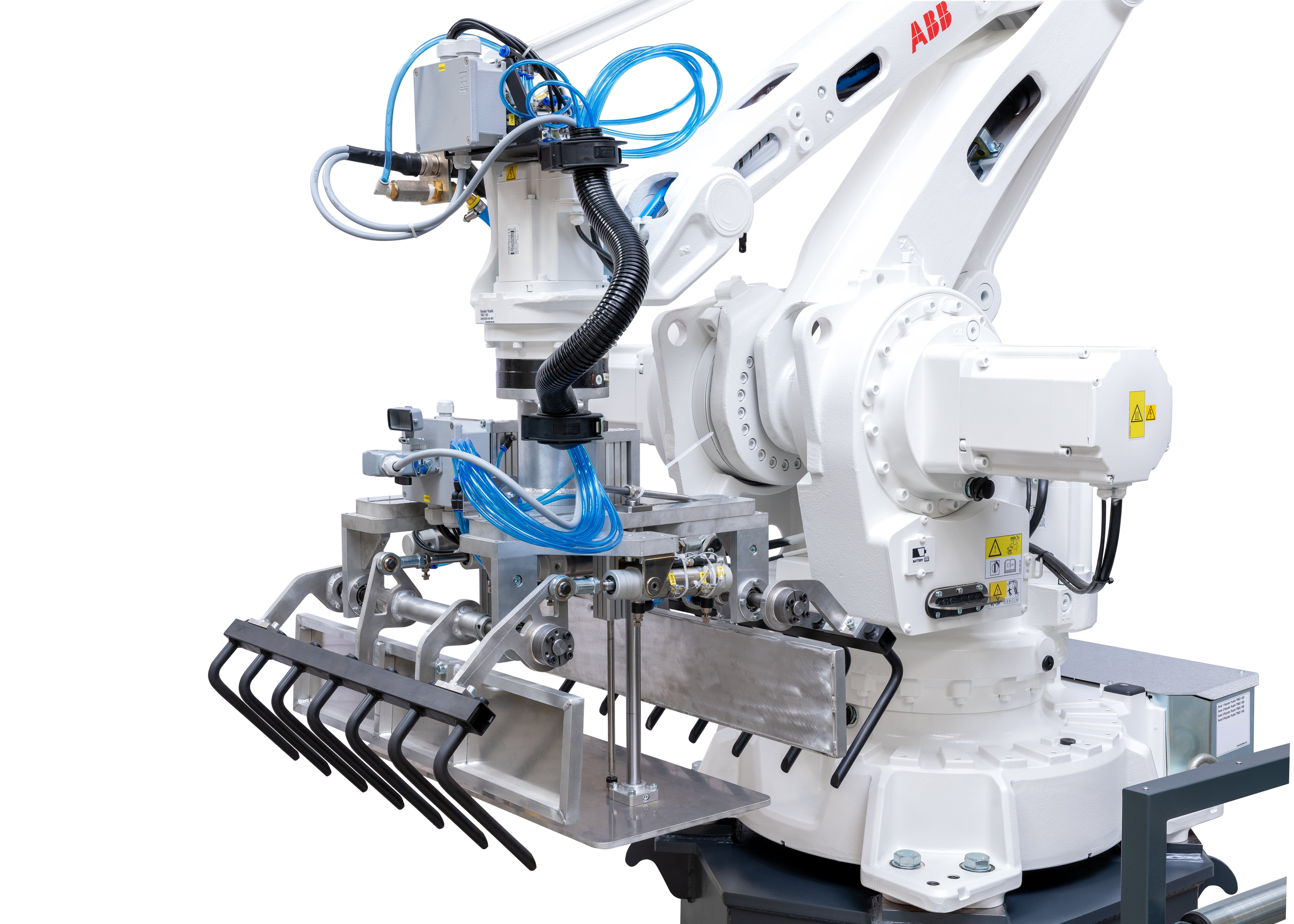

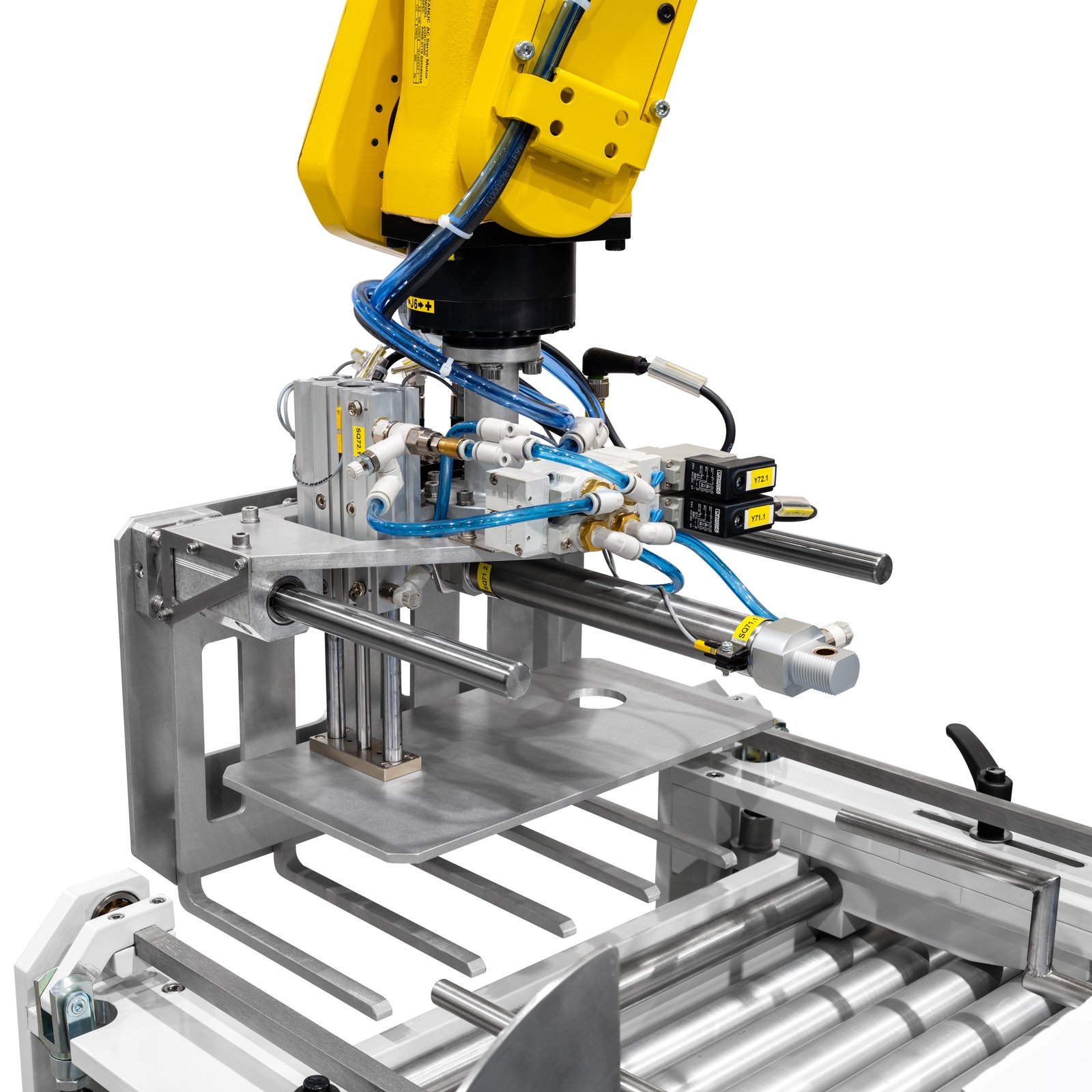

Using a FANUC robotic gripper or suction cups, it arranges the goods into a pre-programmed layout and number of layers on the pallet.

ROBO PAL is usually part of a complete packaging line, where full automation is required—from goods supply, primary and secondary packaging, to pallet placement. Each application is individually tailored, and we configure specific solutions based on the customer’s requirements.

The completed pallet can either be moved manually using a pallet truck or automatically transported via roller conveyors to a wrapping machine.

The technology handles various packaging types and formats (height, width, length) and allows simple reconfiguration for different sizes.

Advantages of ROBO PAL Robotic Palletization

Speed and Efficiency: The robot can handle pallets much faster than manual labor.

Accuracy and Stability: Minimizes errors and product damage.

Flexibility: Easily reconfigurable for different package formats and types.

Safety: Eliminates manual handling of heavy loads.

Cost Savings: Reduces labor costs and losses from damaged goods.

Accessories and Add-ons. Consider integrating ROBO PAL with additional equipment:

Automatic roller conveyors

Wrapping machines

Safety fencing

FAQ – Frequently Asked Questions

What is a palletizer and how does it differ from a palletizing line?

A palletizer is a robotic device designed to stack goods on a pallet. A palletizing line covers the entire process from goods supply to packaging and pallet placement.Is ROBO PAL suitable for smaller lines?

Yes, the system is modular and flexible, suitable for both small and large production lines.How quickly can the system be implemented?

Implementation typically takes 12–20 weeks, depending on the line’s complexity and type of goods.Can the system handle different types of packaging?

Yes, ROBO PAL can handle cartons, bags, and specialized packaging.Is special training required for operators?

Yes, we provide training to ensure the system is operated safely and efficiently.