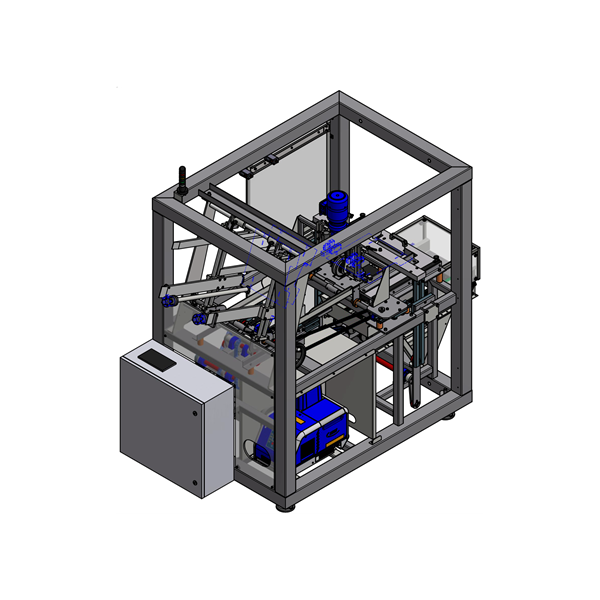

Carton erectors are devices for production automation. The device ensures automatic erecting of the cardboard package (box, tray), bending the flaps and gluing of the bottom of the box. The boxes are stored flat, unfolded in a stacker magazine (blanks). The erected box is then moved to be filled with the product either manually or automatically (filling is not part of the machine). The next step is to close the box with flaps and with tape or hot melt by Nordson glue unit. The device can work with different sizes of cardboard boxes and trays. All functions of the line are controlled via the touch screen. The required size of the carton is set on an adjustable formatting matrix. Drives are handled by servomotors in combination with asynchronous drives and pneumatic elements for fast and smooth operation. The carton storage magazine can be adjusted in 2 axes, the adjustment is carried out by hand wheels (length, width, depth of the carton).

Search term must have more than 2 characters.