Search term must have more than 2 characters.

TOBOGAN 350 STABILO

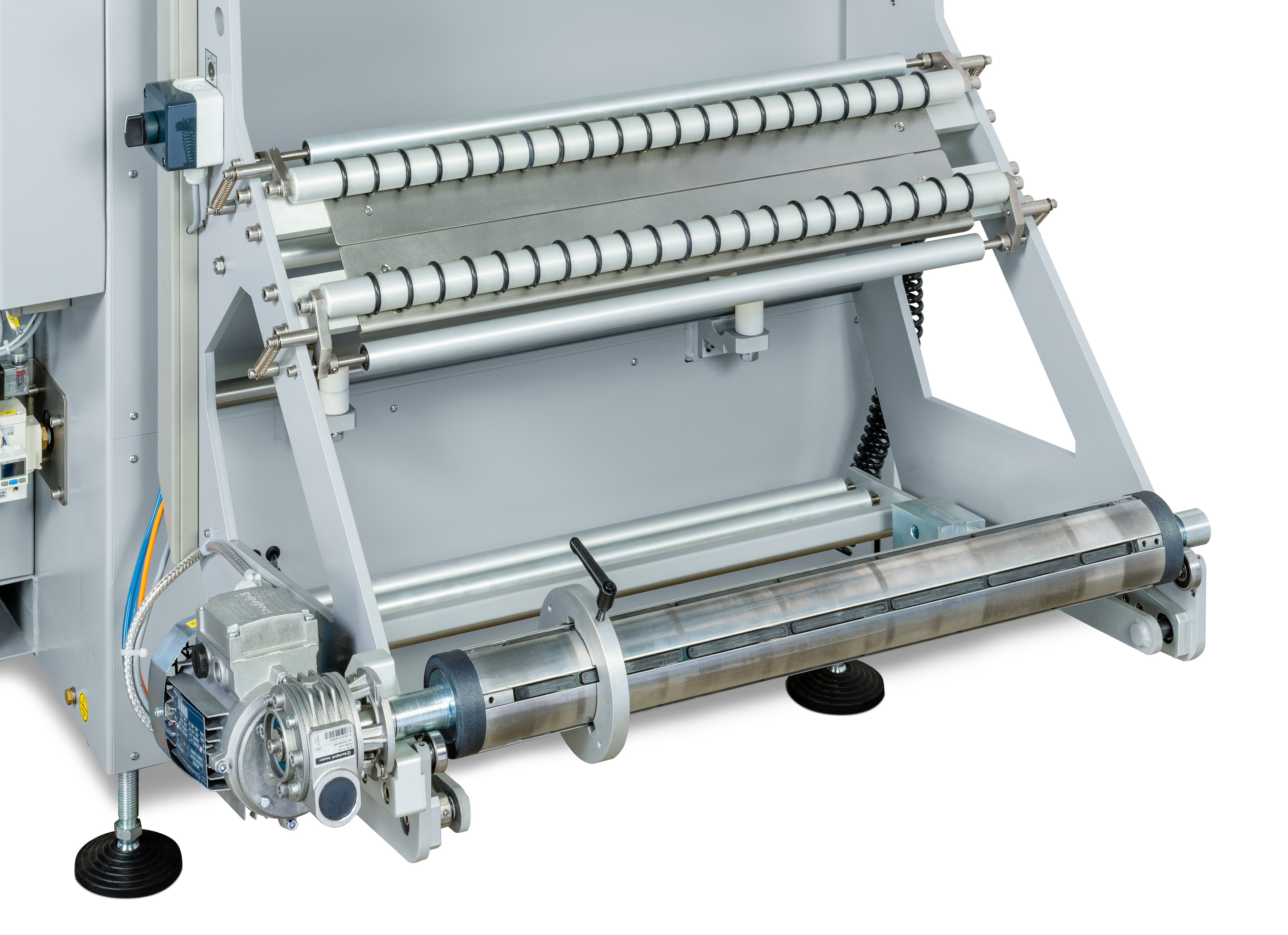

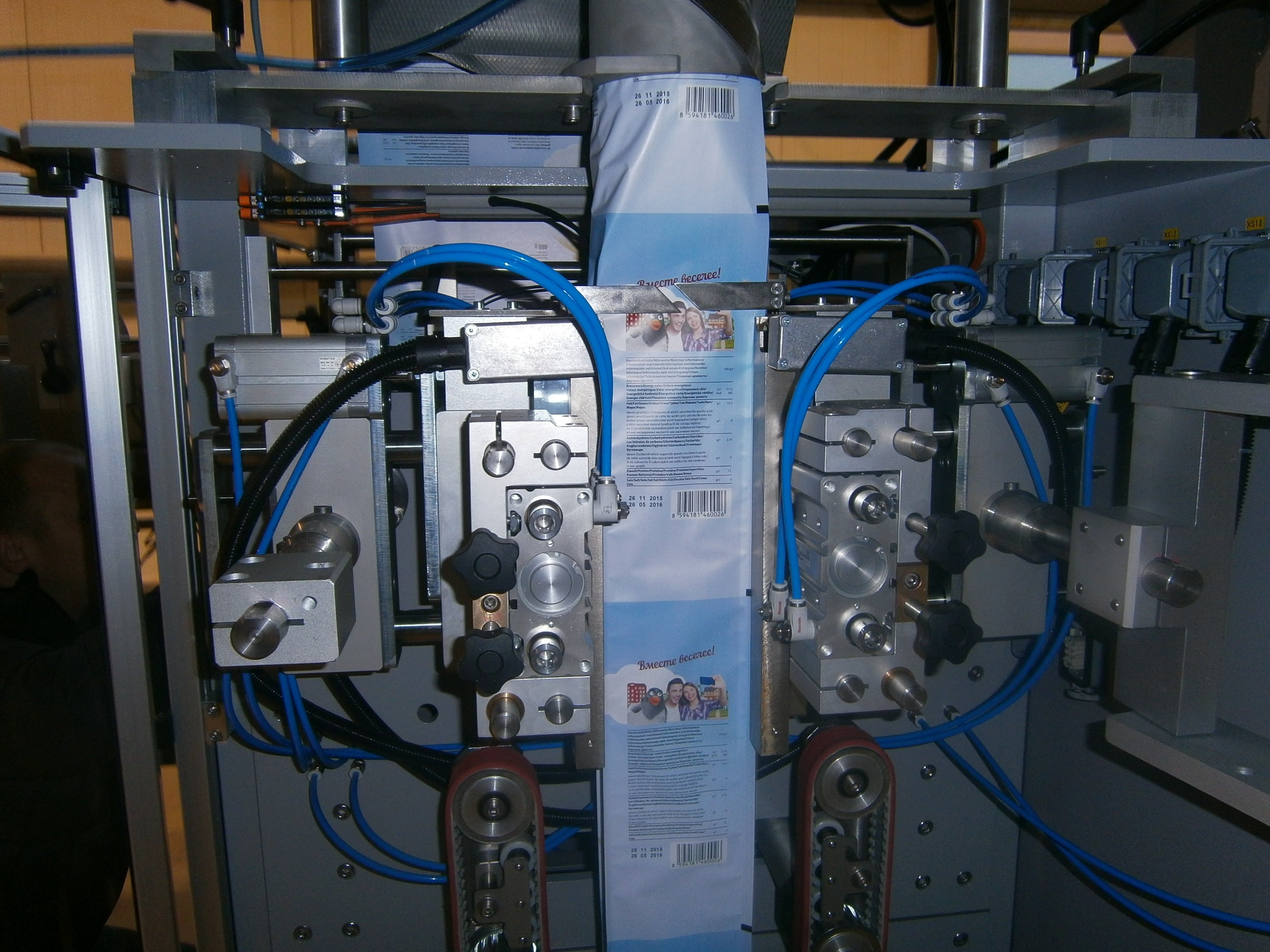

Attractive self-standing Stabilo bags with sealed edges are the first to attract the attention of the end customer. The universal and variable Tobogan 350 STABILO makes such bags without any problems, and it is also simple and intuitive to use. It has a robust construction, the possibility of applying a wide range of additional accessories, as well as the possibility of using the machine independently or including it in a complete filling, packaging and cartoning line. The machine is intended for creating bags of larger volume from a roll of thermally or impulse-sealable packaging material with simultaneous edge sealing. The packaging machine is equipped with a control system with the possibility of program preselection, film centering, remote machine management, additional devices for forming bags and other functions. Package size up to 8.5 l.

Machine output:

up to 80 packs/min.

Dose size:

up to 8500 ccm

Bulk commodities:

salt, coffee, sugar and other loose products

salt, coffee, sugar and other loose products

Powder commodities:

ground spices, washing powder, cocoa, flour and more

ground spices, washing powder, cocoa, flour and more

Liquid commodities:

ketchup, mustard, oil and other liquids

ketchup, mustard, oil and other liquids

Piece commodities:

pasta, chips, candy, frozen vegetables and others

-

CHARACTERISTIC

- Control system: B&R programmable, touch screen

- Machine drives: decentralized, electromechanical, combined with pneumatic

- Sealing type: heat (PP), impulse (PE)

- Machine cycle: discontinuous

- Safety features: main switch, Emergency Stop, end switches on the door

- Sensors: foil end, foil centering, printing mark …

- Surface: varnished steel, stainless steel

- Packaged products: loose (difficult-flowing, dusty), small pieces, liquid

- Types of bags: flat, with folded bottom, with euro-hole, additionally formed block bag, possible to apply zipper

- Bag forming: from a roll of heat or impulse sealable packing material

- Others: smooth change of bag length, machine output, advance of product

free compilation of configuration and display of error messages on the control panelmodification of the program via modem

storage of up to 100 programs / parameters

remote diagnostics and basic service

-

BAG TYPES

Pillow bag

Pillow bag

Pillow 3SS + eurohole

Pillow 3SS + eurohole

Pillow 3SS + eurohole + folded corners

Pillow 3SS + eurohole + folded corners

Pillow 3SS + ironed edges

Pillow 3SS + ironed edges

Block bottom + carry holes

Block bottom + carry holes

Block bottom + sealed stabilo edges

Block bottom + sealed stabilo edges

Block bottom + sealed stabilo edges + zipper

Block bottom + sealed stabilo edges + zipper

-

PARAMETERS

- Bag width: 73-400 mm, with the possibility of changing to other formats

- Bag length: 60-480 mm standard (max. 690 mm)

- Bottom dimensions: with sealed edges 180 x 90 mm

- Foil roll diameter: max 450 mm

- Foil core diameter: 60-76 mm

- Foil width: max 850 mm

- Dimensions: machine frame height 2000 mm + 500 mm filling tube inlet | depth 2000 mm | width 1550 mm

- Weight: 900 kg

- Mechanical output: up to 80 bags/min.

- Output with dosing: depending on product type, packing material and packed amount

-

ACCESSORY

- dosing equipment: volumetric, auger, liquid pumps, linear weighers, combination weighers

- conveyors: feeding, belt, screw, exit

- marking device (date, bar code, expiry date, etc.)

- labelling equipment

- bags counter

- checkweighers

- metal detectors

- system for cross seal precut (easy opening)

- seal perforation - cutting of bag chains with X pieces

- device for punching a euro hole or a round hole for hanging

- device for filling bags with inert gas

- device for extracting excess air from bags

- inclusion of the machine in a complete line of group packaging and palletising

Are you interested in our vertical packaging machine TOBOGAN 350 STABILO?

You are certain to choose from our wide portfolio of packaging equipment. I will help you recommend the most suitable solution. Contact me.