For more than 25 years, Agroracio had been packaging multi-component granular fertilizers by hand. Two to four employees per shift filled buckets from bulk bags, sealed them, and placed them on a pallet. However, manual packaging was physically demanding, slow, and also brought the risk of product contamination and batch inaccuracy.

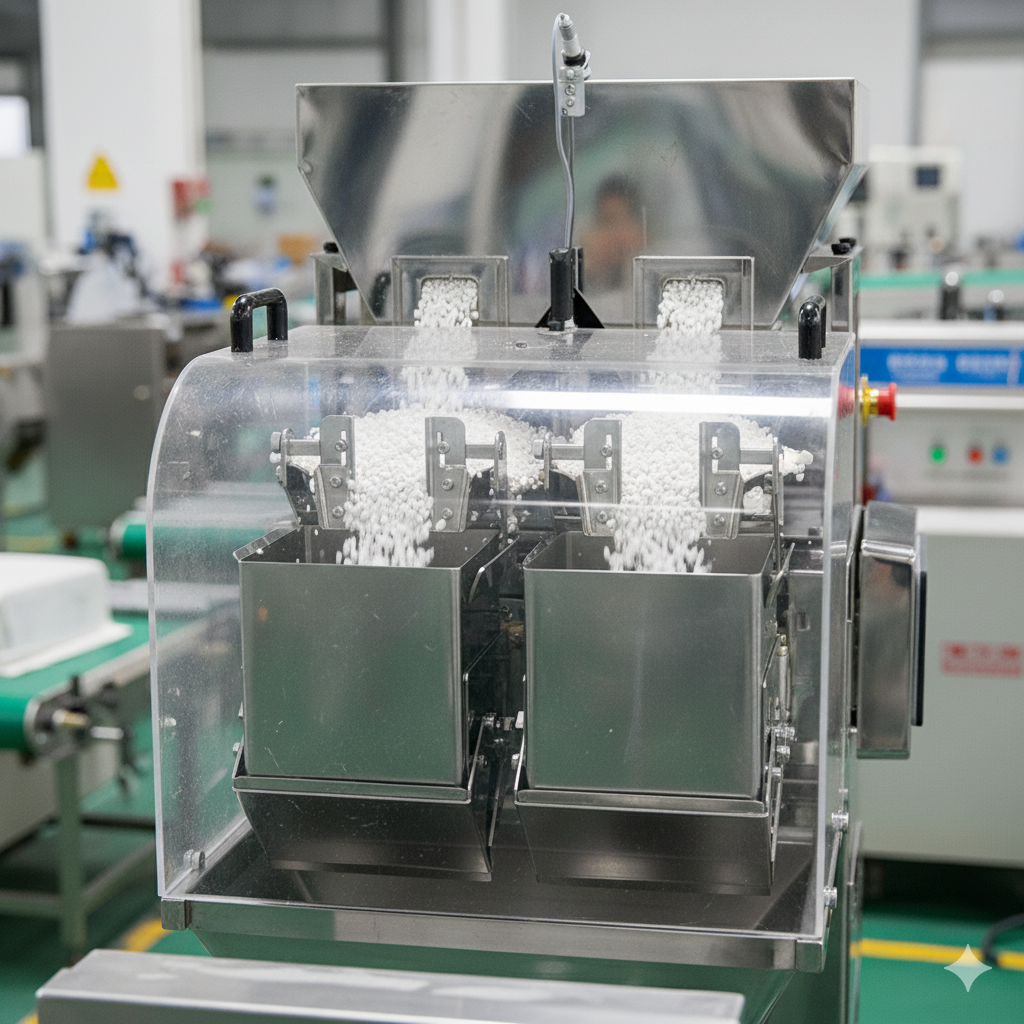

In order to handle higher production volumes and reduce dependence on manual labor, the customer decided to invest in automation. The project resulted in the production of a completely new type of machine for automatically packaging fertilizer into buckets of various volumes.