Do you want to package food products quickly and hassle-free?

Discover how we can help – real production experience in our case study.

Do you want to package food products quickly and hassle-free?

Discover how we can help – real production experience in our case study.

Food packaging is a matter of performance, accuracy, and operational reliability for manufacturing companies. One of the largest breakfast mix producers in the Czech Republic was looking for a solution to handle higher order volumes without compromising quality. The result is a fully automated packaging and cartoning line that today handles everything from product supply, through mixing several components and dosing, to filled bags and full, closed boxes.

The previous technology hit limits in speed and manual insertion of bags into boxes. Key management requirements: fast, precise, and hygienic food packaging.

And when we say fast, we mean machines capable of up to 100 bags per minute.

TOBOGAN 250S vertical packaging machine with an auger doser RACKET S - for packaging larger portions of powder and granular mixes.

TOBOGAN 250C continuous vertical packaging machine with ISHIDA multihead weighers - up to 100 packs/min., minimizes dose deviations, allows quick adjustments, and reduces product waste.

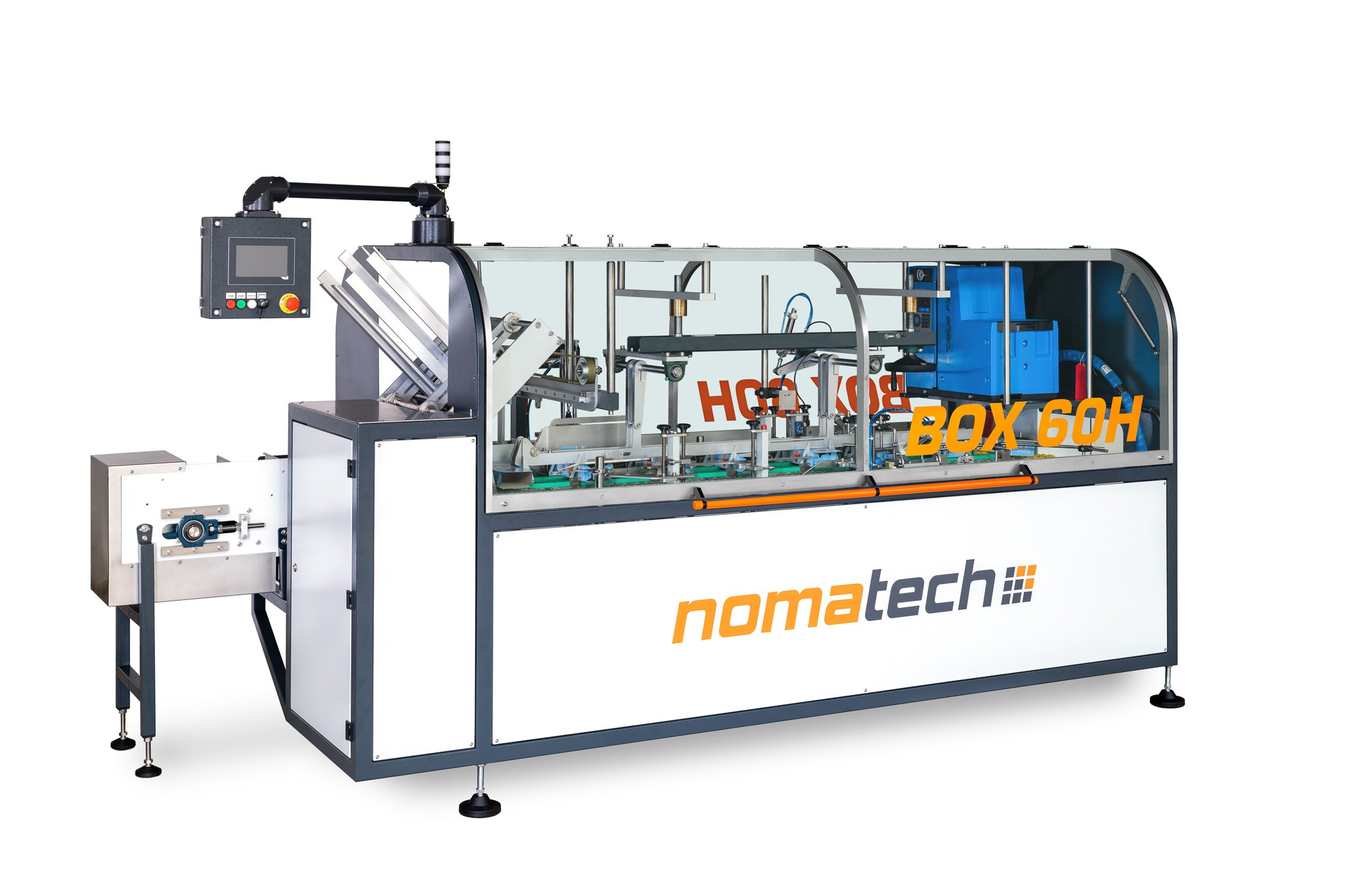

BOX 60H cartoning machine - custom-integrated with conveyors, picks up bags directly from the line, and automatically inserts them into boxes. One of the main challenges was integrating with the existing conveyor system, which we fine-tuned directly in production.

Advantages: minimal manual work, possibility to adjust to different sizes and types of packaging, reliable performance even at high line speeds.

The entire line is designed to handle not only bag production but also mixing individual components directly in production if needed.

The project was implemented in a new facility – an ideal opportunity to start food packaging without compromises. From initial design to installation of all food packaging machines and cartoning equipment, integration with conveyors, and operator training – the entire line was built tailor-made.

Faster production

More precise packaging

Full automation

Improved hygiene

Fewer errors

Do you have a similar project?

We have extensive experience designing lines that meet customer requirements, products, and space constraints. We can design a line for you the same way.

👉 Contact us and we’ll build it together.