Search term must have more than 2 characters.

NEWS | BLOG

CASE STUDY: Automatic fertilizer packaging at Agroracio

For more than 25 years, Agroracio had been packaging multi-component granular fertilizers by hand. Two to four employees per shift filled buckets from bulk bags, sealed them, and placed them on a pallet. However, manual packaging was physically demanding, slow, and also brought the risk of product contamination and batch inaccuracy.

In order to handle higher production volumes and reduce dependence on manual labor, the customer decided to invest in automation. The project resulted in the production of a completely new type of machine for automatically packaging fertilizer into buckets of various volumes.

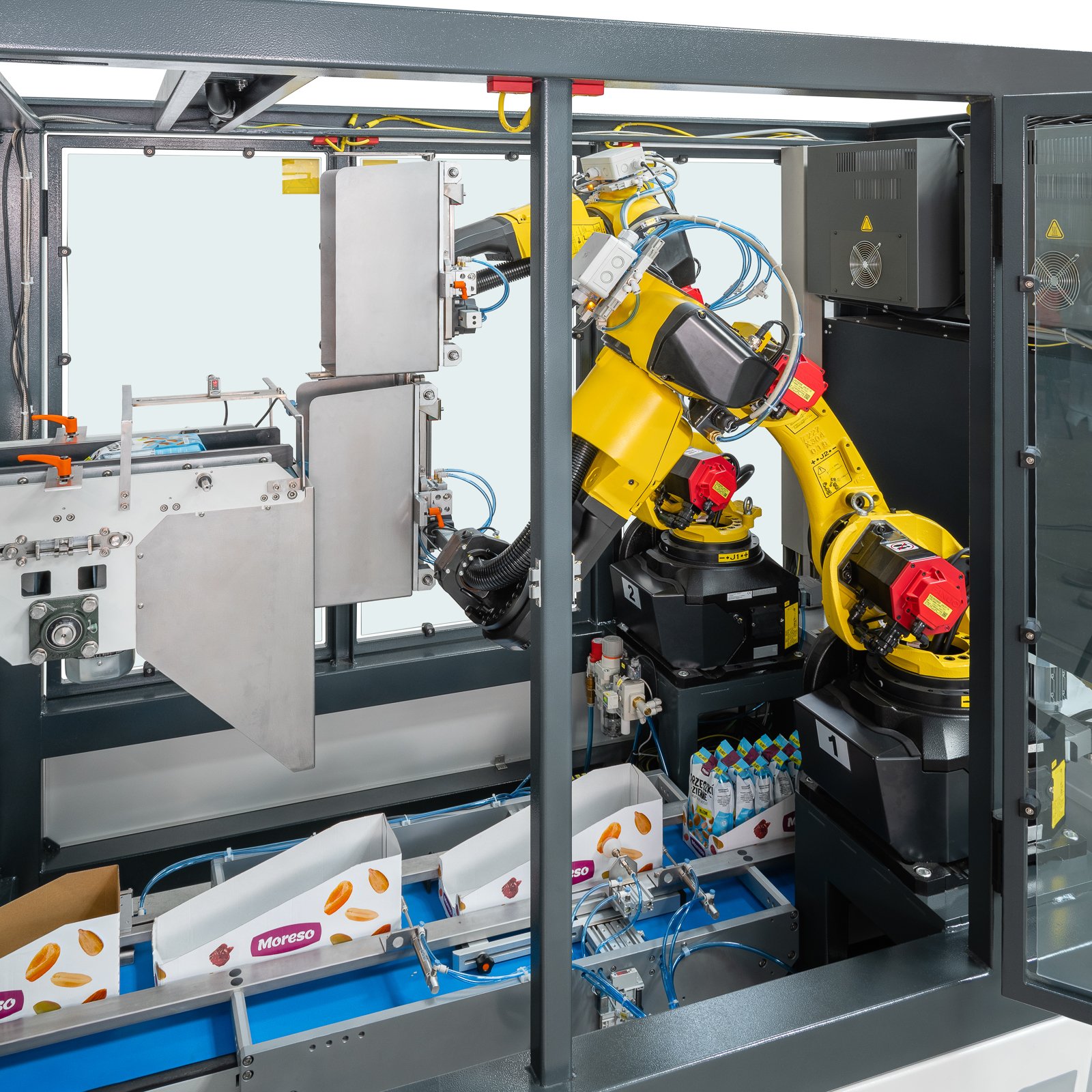

CASE STUDY: Food Packaging Automation

How to pack thousands of jars and pouches in a limited space – and reduce the environmental footprint at the same time?

Czech food company was looking for a way to replace its aging cartoning system for filled jars and move towards more sustainable food packaging.

The goal was to replace the paper tray and shrink PE film with a fully recyclable cardboard package.

The second challenge was to automate the packaging of single-portion pouches (100 ml) of tartar sauce and mayonnaise, which had previously been assembled manually.

And all of this within limited space.

Czech food company was looking for a way to replace its aging cartoning system for filled jars and move towards more sustainable food packaging.

The goal was to replace the paper tray and shrink PE film with a fully recyclable cardboard package.

The second challenge was to automate the packaging of single-portion pouches (100 ml) of tartar sauce and mayonnaise, which had previously been assembled manually.

And all of this within limited space.

You’ll soon see our technology in Ukraine

Czech packaging technologies are heading abroad again! The TOBOGAN 250S vertical machine will be on display at the Agro2Food fair in Kiev this year thanks to our partner GVP.

CASE STUDY: Automated food packaging – how breakfast mixes are made

Do you want to package food products quickly and hassle-free?

Discover how we can help – real production experience in our case study.

COMPANY ANNUAL HOLIDAY 2025

NOMATECH s.r.o. will be closed due to annual summer holiday from 21st July to 1st August 2025.

When your machine stays in the organizer’s showroom after the trade fair…

On 27th-29th May, 2025, the traditional Robotic Opportunities Fair (VRP) will take place at FANUC's Prague headquarters - an event for everyone interested in modern automation and robotics. This year, more than 20 partners and 18 system integrators will be presenting at this event, demonstrating 30 robotic applications in real operation. NOMATECH will be one of them.

CASE STUDY: Muesli that tastes the same every time

At MIXIT, they know that every handful of muesli must be just as good as the last – and the next. That’s why we built a new line together for mixing and packaging muesli into sachets. The line ensures accurate dosing, quality control, and attractive packaging for every portion.

Come experience the future of cartoning with NOMATECH at the Robotic Opportunities Fair 2025 (Veletrh Robotických Příležitostí 2025)

On 27th-29th May, 2025, the traditional Robotic Opportunities Fair (VRP) will take place at FANUC's Prague headquarters - an event for everyone interested in modern automation and robotics. This year, more than 20 partners and 18 system integrators will be presenting at this event, demonstrating 30 robotic applications in real operation. NOMATECH will be one of them.

SHALL WE MEET AT WARSAW PACK 2025?

Shall we meet at Warsaw Pack 📦 2025? This year, the packaging technology fair takes place from April 8 to 10.